ENGLISH

OM-230 915 Page 7

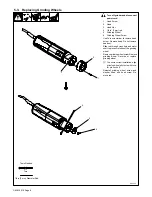

5-2.

Grinding And Cutting Electrodes

804 719

!

Grinding the tungsten electrode

produces dust and flying sparks

which can cause injury and start

fires. Use local exhaust (forced

ventilation) at the grinder or wear

an approved respirator.

Read MSDS for safety informa-

tion. Consider using tungsten

containing ceria, lanthana, or yt-

tria instead of thoria. Grinding

dust from thoriated electrodes

contains low-level radioactive

material. Properly dispose of

grinder dust in an environmen-

tally safe way. Wear proper face,

hand, and body protection. Keep

flammables away.

Do not exert excessive pressure on

the grinding wheel or the life of the

wheel will be shortened.

Use a rough grinding wheel to

sharpen large electrodes.

Wait until grinding wheel stops be-

fore restarting grinder.

1

Tungsten Electrode

To Sharpen Electrode:

Determine diameter of electrode and

desired sharpening angle.

Turn on grinder. Insert electrode in cor-

responding hole in grinder.

Slowly turn the electrode until tip is

sharpened evenly. If the electrode is not

turned the tip will be flat ground to the

selected angle.

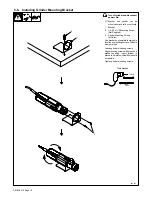

To Face Grind Electrode:

Determine diameter of electrode.

Turn on grinder. Insert electrode in cor-

responding hole at front of grinding

head. Grind the electrode tip until

square.

To Cut Electrode To Length:

(For Orbital Or Manual Welding):

2

Cutting Slot

Turn on grinder. Insert electrode in cut-

ting slot and turn electrode slowly until

cut.

An optional cutting device is avail-

able for larger electrodes. See Sec-

tion 7.

Turn grinder off.

Sharpening Electrode

Face Grinding Electrode

Cutting Electrode To Length

1

1

1

2