OM-230 915 Page 4

SECTION 3 − SPECIFICATIONS

3-1.

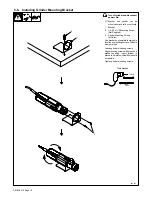

Description

The TTG Plus cuts, grinds, and faces tungsten electrodes used in the TIG (GTAW) welding process. Additional fea-

tures and benefits of this unit are:

•

Electrodes are sharpened to conform to recognized standards.

•

The replaceable grinding wheel is diamond-coated on both sides.

•

The grinding wheel has an offset edge for easy cutting − an industry exclusive!

•

The head assembly allows for different electrode angles and diameters.

•

The unit can be hand operated, or bench-mounted using the supplied mounting bracket.

Grinding the tungsten electrode produces dust and flying sparks which can cause injury and start fires. Use local exhaust (forced

ventilation) at the grinder or wear an approved respirator.

Read MSDS for safety information. Consider using tungsten containing ceria, lanthana, or yttria instead of thoria. Grinding dust from

thoriated electrodes contains low-level radioactive material. Properly dispose of grinder dust in an environmentally safe way. Wear

proper face, hand, and body protection. Keep flammables away.

3-2.

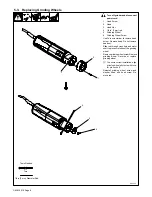

Included With Your Unit

1

TTG Plus Tungsten Grinder

With Diamond Grinding Wheel

2

Steel Carrying Case

3

Electrode Holder With

Clamping Collet

4

Torx Screwdriver

5

Mounting Bracket

804 716 / Ref 804 762

1

2

4

3

5

3-3.

Specifications

Dimensions

Weight

Input Power

Power-On Time

Cord

Length

Rotary

Speed

2.6 x 13.8 in.(65 x 250

mm)

3 lb (1.4 kg)

(w/Grinding Wheel)

110 V AC

50/60 Hz

(500 watt Rating)

100%

9.8 ft

(3 m)

30,000

RPM

(U/min)

Noise

Rating

Vibration

Level

Electrode

Material

Electrode Angles

Electrode Diameters

83 dBa

(per EN23741)

2.5 m/s

2

(per EN28662, Part 1)

Tungsten electrodes alloyed with

zirconium, lanthanum, yttrium,

and cerium

Consult country-specific reg-

ulations for electrodes con-

taining Thorium.

15

°

18

°

22.5

°

30

°

0.04 in.(1 mm)

1/16 in.(1.6 mm)

3/32 in.(2.4 mm)

1/8 in.(3.2 mm)

5/32 in. (4 mm)