2

How It Operates

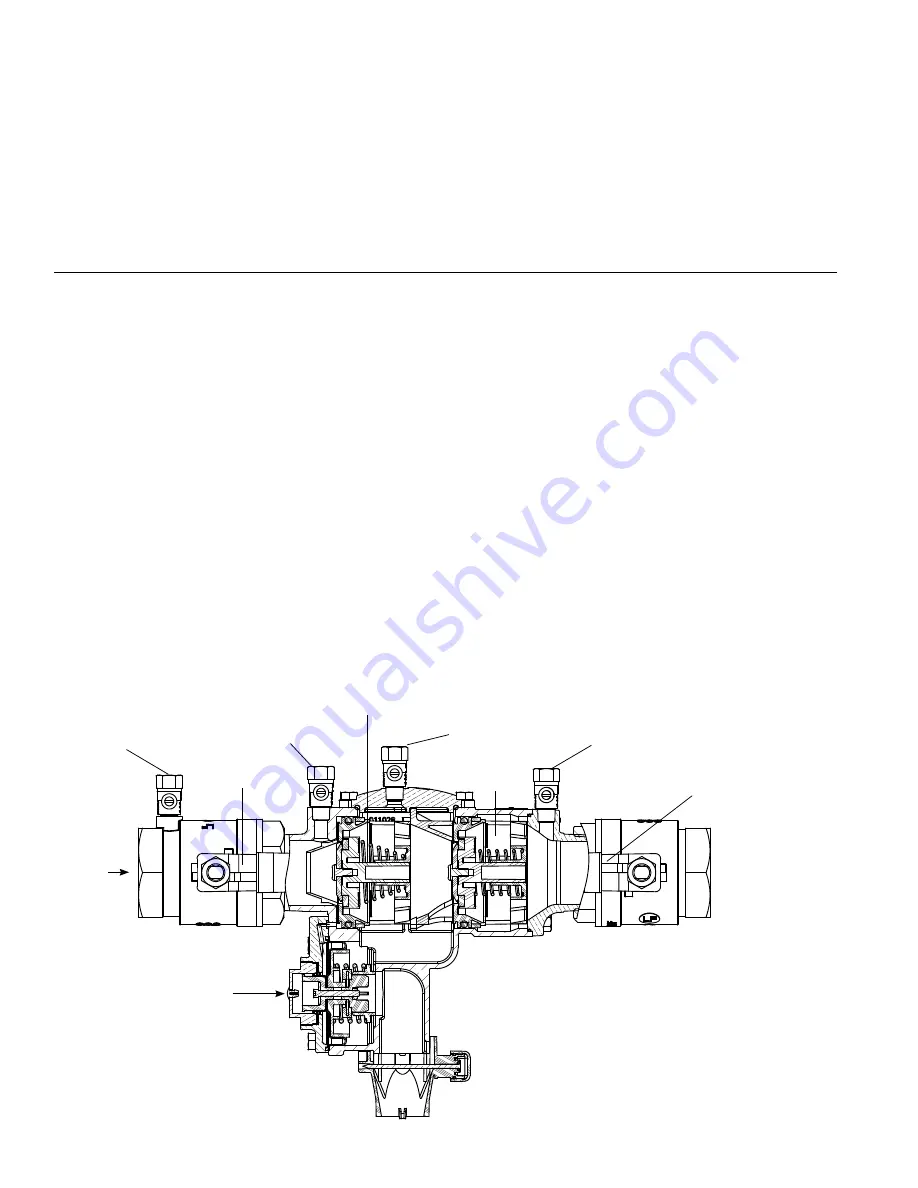

The FEBCO Series 860 Reduced Pressure Zone backflow preventer

assembly consists of two independently operating, spring loaded

check valves with a pressure differential relief valve located between

the two checks. The pressure drop across the first check valve

is approximately 7.0 psid with no flow. The relief valve consists of

a hydraulically balanced diaphragm with the high pressure side

hydraulically connected to the upstream pressure zone. The relief

valve remains closed during normal operation. The low pressure side

of the diaphragm is spring loaded to force the relief valve to open

when the pressure drop across the first check and the diaphragm is

reduced to approximately 3.0 psid. A complete assembly includes

two shutoff valves and four test cocks.

Service Procedures

FEBCO backflow prevention assemblies can be serviced with

standard tools and are designed for ease of maintenance. The

assemblies can be serviced in line, eliminating the need to remove

and reinstall a unit.

Suggested Tool Kit

• 1 crescent wrench

• 1 medium standard screwdriver

• Differential pressure test kit

• 1 medium Phillips screwdriver

• Box/open end wrench

1. Flush the line clean of debris before assembly installation. The

most common cause of check fouling and relief valve discharge is

dirt and debris in the seating areas.

2. To flush the line after installation, slowly close the inlet shutoff

valve, remove the cover and spring assemblies of both check

valves, and open the inlet shutoff valve to allow sufficient flow

of water through the assembly. Clear all sand, debris, and other

particles from the line. If debris in the water continues to cause

fouling, consider installation of a strainer upstream of the assembly

if in compliance with local codes.

3. Rinse all parts with clean water before reassembly.

4. Carefully inspect diaphragms, seals, and seating surfaces for

damage or debris. If the check valve seat disc has been severely

cut at the seat ring diameter, the assembly has been subjected

to extremely high and repeated backpressure. Either thermal

water expansion or water hammer is the most likely cause. If

backpressure persists, consider installation of a pressure relief

valve downstream of the assembly.

5. Use caution to avoid damaging any guiding surfaces while

handling parts. Do not force parts together. The O-ring seals

used in FEBCO assemblies require only a small tightening force to

ensure a positive seal.

6. Test the unit after servicing in accordance with locally approved

test methods to ensure proper operation; see the "Testing"

section.

7. Use the exploded drawings and parts list for visual aid information;

see the "Parts" section.

8. Apply a thin coating of the lubricant supplied in the repair kit to the

O-rings and other seals as directed. Any additional lubricants in

use must be FDA Approved food-grade petroleum jelly.

Test Cock No. 3

Test Cock No. 4

2nd Check

Module

Relief Valve

Test Cock No. 1

Inlet Shutoff

Valve

Outlet Shutoff

Valve

1st Check Module

Flow

Test Cock No. 2

Cross-section with flood sensor

(Union ball valves not shown)