18

PREMIER 2 SINGLE-SPEED INSTALLATION AND MAINTENANCE MANUAL

Cooling, 2nd Stage (Y1,Y2,O)

The fan changes to high speed (medium in dehumidification mode) 15 seconds after

the Y2 input.

FAN (G Only)

The fan starts on low speed. Regardless of fan input (G) from the thermostat, the fan will

remain on low speed for 30 seconds at the end of each heating, cooling or emergency heat cycle.

LOCKOUT CONDITIONS

During lockout mode, the appropriate unit and thermostat lockout LEDs will illuminate. The

compressor, loop pump, hot water pump and accessory outputs are de-energized. Unless the

lockout is caused by an ECM2 low RPM fault, the fan will continue to run on low speed, and if the

thermostat calls for second- or third-stage heating, emergency heat operation will occur.

Lockout modes of any kind can be reset at the thermostat after a 5 second waiting period,

which restores normal operation but keeps the unit lockout LED illuminated. Interruption of power

to the unit will reset a lockout without a waiting period and clear all lockout LEDs.

High Pressure

This lockout mode occurs when the normally closed safety switch is momentarily opened.

Low Pressure

This lockout mode occurs when the normally closed switch is opened for 30 continuous

seconds.

Freeze Protection (Water Flow)

This lockout mode occurs when the freeze thermistor temperature (located between the TXV

and coax) is at or below the selected freeze protection point (well 30

°

F or loop 15

°

F) for 30

continuous seconds.

Condensate Overflow

This lockout mode occurs when the condensate overflow level has been reached for 30

continuous seconds.

Fan RPM

The Premier 2 control board monitors fan RPM to sense if the fan is operating. This lockout

mode occurs if the fan RPM falls below the low RPM limit (100 RPM) for 30 continuous seconds.

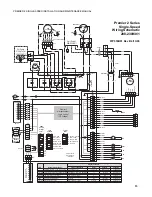

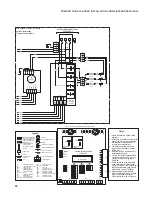

AIRFLOW SELECTION DIP SWITCHES (SW1)

See Fan Speed section on page 19.

FIELD SELECTION DIP SWITCHES (SW2)

An 8-position DIP switch package on the Premier 2 control allows the following field select-

able options:

1-Service Test Mode

This DIP switch on the control allows field selection of normal or test operational modes. The

test mode accelerates most timing functions 16 times to allow for faster troubleshooting. Test

mode also allows viewing the current status of the fault inputs on the LED display.

2-Freeze Protection Setting

This DIP switch allows field selection of freeze thermistor fault sensing temperatures for well

water or antifreeze protected earth loops.

3-Accessory Relay

This DIP switch allows field selection of the accessory relay to operate with the compressor or fan.

Содержание AT019D

Страница 20: ......

Страница 21: ......

Страница 26: ...26 PREMIER 2 SINGLE SPEED INSTALLATION AND MAINTENANCE MANUAL Notes...

Страница 27: ...27 PREMIER 2 SINGLE SPEED INSTALLATION AND MAINTENANCE MANUAL...