11

PREMIER 2 SINGLE-SPEED INSTALLATION AND MAINTENANCE MANUAL

CAUTION:

Never operate the DHW circulating pump while dry.

Steps:

1)

Make sure that any valves in the desuperheater water circulating circuit are open.

2)

Turn on the Premier 2 unit to first stage heating.

3)

The DHW pump should be running. Be sure the disable switch for the DHW pump (SW4) is

ON. The DHW OFF LED on the unit should not be illuminated.

4)

The temperature difference between the water entering and leaving the desuperheater

should be 5

°

F to 15

°

F. The water flow should be approximately 0.4 gpm per ton of nominal

cooling.

5)

Allow the unit to heat water for 15 to 20 minutes to be sure operation is normal.

6)

When the pump is first started, open the inspection port (if equipped) until water dribbles out,

then replace. Allow the pump to run for at least five minutes to ensure that water has filled

the circulator properly.

DESUPERHEATER NOTE:

When servicing a unit’s refrigeration circuit, it is always good practice to disable the desuper-

heater pump. This can be accomplished by using the DHW pump disable switch located on the

front of the unit cabinet near the LED annunciator panel. The red DHW OFF LED will illuminate,

indicating the DHW pump is disabled. Do not run DHW pump while dry. If the unit is placed in

operation before the desuperheater piping is connected, be sure that the pump switch is

set to the OFF position.

GENERAL

Be sure the available power is the same voltage and phase as that shown on the unit serial

plate. Line and low voltage wiring must be done in accordance with local codes or the National

Electric Code, whichever is applicable.

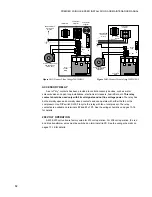

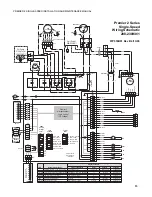

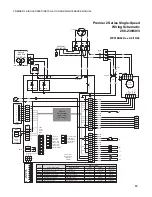

UNIT POWER CONNECTION

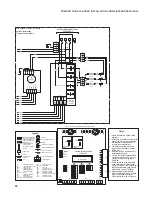

Connect the incoming line voltage wires to the “L” side of the contactor as shown in Figures

4A and 4B on page 12. Consult the Unit Electrical Data section on page 25 for correct wire and

fuse size.

EXTERNAL LOOP PUMP POWER CONNECTION

If the unit is to be used with an external loop pump (FC1 or FC2 flow center), the pump(s) will

be connected to the terminals on PB1 in the unit electrical box as shown in Figures 4A and 4B on

page 12. The pumps will automatically be cycled as required by the unit or by a slave signal from

another Premier 2 unit sharing the flow center (see Figure 8 on page 8).

Electrical

Connections

Содержание AT019D

Страница 20: ......

Страница 21: ......

Страница 26: ...26 PREMIER 2 SINGLE SPEED INSTALLATION AND MAINTENANCE MANUAL Notes...

Страница 27: ...27 PREMIER 2 SINGLE SPEED INSTALLATION AND MAINTENANCE MANUAL...