has caught fire adjust the primary air settings

to suit the heat requirements.

2.

The logs will burn slowly towards the rear of

the fire chamber and the rate of burning is

adjustable at all times by means of the pri-

mary air settings. The more air (wider open

ing) the faster the burning. Do not overfire

the stove. If the stove or chimney connector

glows, you are overfiring the stove.

3.

When the fire is reduced to embers, open the

door and carefully rake the embers towards

the front of the fire chamber and reload with

logs. After fuelling the stove hold the fire

door (part number 6) cracked open for 3-5

minutes to enhance combustion, close the

fire door (item 6) and adjust the Primary air

settings to give the required heat output.

4.

Keep all combustible materials at least three

feet away from the stove and connector

pipes. Never dry clothing on or over the

stove or within three feet of it.

5.

Use the main top of the stove for boiling, sim-

mering etc. You will soon learn the best

ways and means of using the stove in order

to attain maximum efficiency.

6.

Disposal of Ashes - Ashes should be

placed in a metal container with a tight fitting

lid. The closed container of ashes should be

placed on a non-combustible floor or on the

ground, well away from all combustible

materials, pending final disposal. If the

ashes are disposed of by burial in soil or oth-

erwise locally dispersed, there should be

retained in the closed container until all cin-

ders have thoroughly cooled.

7.

Creosote - Formation and Need for

Removal when wood is burned slowly, it pro

duces tar and other organic vapours, which

combine with expelled moisture to form cre-

osote. The creosote vapours condense in

the relatively cool chimney flue of a slow-

burning fire. As a result, creosote residue

accumulates on the flue lining. When ignited

this creosote makes an extremely hot fire.

The chimney connector and chimney should be

inspected at least twice monthly during the heating

season to determine if a creosote build-up has

occurred. If creosote has accumulated it should be

removed to reduce the risk of a chimney fire.

Inspect the chimney connector frequently. Tap the

connector with your finger when the pipe is cool. If

you hear a dull echo, the pipe may need cleaning.

Disassemble the chimney connector and clean the

sections. Replace corroded pipe sections. The fit-

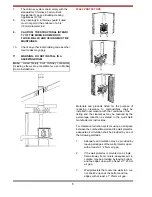

ting of a slip-joint in the stove pipe makes the dis-

mantling easy for cleaning and inspection of chim-

ney and stove.

10

2.

Existing fuel-fired equipment in the house,

such as fireplaces or other heating appli-

ances, smell, do not operate properly, suffer

smoke roll-out when opened, or back-draft

whether or not there is combustion present.

3.

Opening a window slightly on a calm

(windless) day alleviates any of the above

symptoms.

4.

The house is equipped with a well-sealed

vapour barrier and tight fitting windows

and/or has any powered devices that

exhaust house air. (e.g. Extraction Hood or

Tumble Dryers etc..)

5.

There is excessive condensation on win-

dows in the winter.

6.

A ventilation system is installed in the house.

If these or other indications suggest that infiltration

air is inadequate, additional combustion air should

be provided from the outdoors. Outside combustion

air can be provided to the appliance by the following

means:

1.

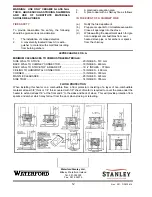

Direct connection: Refer to O.S.A. Hook-up

in this manual.

2.

Indirect method: for an appliance not

certified for direct connection of outside

combustion air, the outside air is ducted to a

point no closer than (12”) 300mm from the

appliance, to void affecting the performance

of the appliance.

3.

A mechanical ventilation system: if the

house has a ventilation system (air change

or heat recovery):

a. The ventilation system may be able

to provide sufficient combustion make-up

air for the solid-fuel-fired appliance.

b. The householder should be informed that

the ventilation system might need to be

re-balanced by a ventilation technician

after installation of the appliance.

SPILLAGE TEST

1.

Light/burn appliance under normal condi-

tions in accordance with this installation

manual.

2.

Close all doors and windows.

3.

Operate all appliances requiring a full rate

(eg. extraction hoods, tumble dryers etc).

4.

Check for spillage.

LIGHTING

1.

Lay a few crumpled sheets of paper on the

hearth, then a few small sticks or kindling to

get the fire started. Open the fire door and

light paper. Close the door and open the pri-

mary air control ALL THE WAY. The fire will

catch the kindling quickly, after which a full

size log may be placed on top. After the log