●

exhaust gas to exhaust system

●

cooling water from cylinder head to the return pipe

4.2.9

Camshaft and valve mechanism

The cams are integrated in the drop forged shaft material. The bearing journals are made in

separate pieces, which are fitted, to the camshaft pieces by flange connections. The camshaft

bearing housings are integrated in the engine block casting and are thus completely closed.

The bearings are installed and removed by means of a hydraulic tool. The camshaft covers,

one for each cylinder, seal against the engine block with a closed O-ring profile.

The valve tappets are of piston type with self-adjustment of roller against cam to give an even

distribution of the contact pressure. The valve springs make the valve mechanism dynamically

stable.

Variable Inlet valve Closure (VIC), which is available on IMO Tier 2 engines, offers flexibility to

apply early inlet valve closure at high load for lowest NOx levels, while good part-load

performance is ensured by adjusting the advance to zero at low load. The inlet valve closure

can be adjusted up to 30° crank angle.

4.2.10

Camshaft drive

The camshafts are driven by the crankshaft through a gear train.

4.2.11

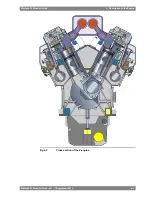

Turbocharging and charge air cooling

The SPEX (Single Pipe Exhaust) turbocharging system is designed to combine the good part

load performance of a pulse charging system with the simplicity and good high load efficiency

of a constant pressure system. In order to further enhance part load performance and prevent

excessive charge air pressure at high load, all engines are equipped with a wastegate on the

exhaust side. The wastegate arrangement permits a part of the exhaust gas to discharge after

the turbine in the turbocharger at high engine load.

In addition there is a by-pass valve on main engines to increase the flow through the

turbocharger at low engine speed and low engine load. Part of the charge air is conducted

directly into the exhaust gas manifold (without passing through the engine), which increases

the speed of the turbocharger. The net effect is increased charge air pressure at low engine

speed and low engine load, despite the apparent waste of air.

All engines are provided with devices for water cleaning of the turbine and the compressor.

The cleaning is performed during operation of the engine.

In-line engines have one turbocharger and V-engines have one turbocharger per cylinder bank.

For in-line engines and 12V32, the turbocharger(s) can be placed either at the driving end or

at the free end. 16V32 and 18V32 have the turbochargers always placed at free end.

The turbocharger is supplied with inboard plain bearings, which offers easy maintenance of

the cartridge from the compressor side. The turbocharger is lubricated by engine lubricating

oil with integrated connections.

A two-stage charge air cooler is standard. Heat is absorbed with high temperature (HT) cooling

water in the first stage, while low temperature (LT) cooling water is used for the final air cooling

in the second stage. The engine has two separate cooling water circuits. The flow of LT cooling

water through the charge air cooler is controlled to maintain a constant charge air temperature.

4.2.12

Fuel injection equipment

The fuel injection equipment and system piping are located in a hotbox, providing maximum

reliability and safety when using preheated heavy fuels. The fuel oil feed pipes are mounted

directly to the injection pumps, using a specially designed connecting piece. The return pipe

is integrated in the tappet housing.

Wärtsilä 32 Product Guide - a21 - 7 September 2016

4-3

4. Description of the Engine

Wärtsilä 32 Product Guide

Содержание WARTSILA32

Страница 18: ...This page intentionally left blank...

Страница 72: ...This page intentionally left blank...

Страница 130: ...This page intentionally left blank...

Страница 150: ...This page intentionally left blank...

Страница 186: ...This page intentionally left blank...

Страница 204: ...This page intentionally left blank...

Страница 210: ...This page intentionally left blank...

Страница 216: ...This page intentionally left blank...

Страница 238: ...This page intentionally left blank...

Страница 246: ...This page intentionally left blank...

Страница 248: ...This page intentionally left blank...

Страница 251: ......

Страница 252: ......

Страница 253: ......