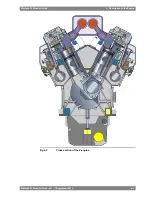

The connecting rods, at the same crank in the V-engine, are arranged side-by-side in order

to achieve standardisation between the in-line and V-engines.

The crankshaft is fully balanced to counteract bearing loads from eccentric masses. If

necessary, it is provided with a torsional vibration damper at the free end of the engine.

4.2.3

Connecting rod

The connecting rod is of forged alloy steel. All connecting rod studs are hydraulically tightened.

Oil is led to the gudgeon pin bearing and piston through a bore in the connecting rod.

The connecting rod is of a three-piece design, which gives a minimum dismantling height and

enables the piston to be dismounted without opening the big end bearing.

4.2.4

Main bearings and big end bearings

The main bearings and the big end bearings are of tri-metal design with steel back, lead-bronze

lining and a soft running layer. The bearings are covered all over with Sn-flash of 0.5-1 µm

thickness for corrosion protection. Even minor form deviations become visible on the bearing

surface in the running in phase. This has no negative influence on the bearing function.

4.2.5

Cylinder liner

The cylinder liners are centrifugally cast of a special grey cast iron alloy developed for good

wear resistance and high strength. Cooling water is distributed around upper part of the liners

with water distribution rings. The lower part of liner is dry. To eliminate the risk of bore polishing

the liner is equipped with an anti-polishing ring.

4.2.6

Piston

The piston is of composite design with nodular cast iron skirt and steel crown. The piston skirt

is pressure lubricated, which ensures a well-controlled lubrication oil flow to the cylinder liner

during all operating conditions. Oil is fed through the connecting rod to the cooling spaces of

the piston. The piston cooling operates according to the cocktail shaker principle. The piston

ring grooves in the piston top are hardened for better wear resistance.

4.2.7

Piston rings

The piston ring set are located in the piston crown and consists of two directional compression

rings and one spring-loaded conformable oil scraper ring. Running face of compression rings

are chromium-ceramic-plated.

4.2.8

Cylinder head

The cylinder head is made of grey cast iron. The thermally loaded flame plate is cooled efficiently

by cooling water led from the periphery radially towards the centre of the head. The bridges

between the valves cooling channels are drilled to provide the best possible heat transfer.

The mechanical load is absorbed by a strong intermediate deck, which together with the upper

deck and the side walls form a box section in the four corners of which the hydraulically

tightened cylinder head bolts are situated. The exhaust valve seats are directly water-cooled.

The valve seat rings are made of specially alloyed cast iron with good wear resistance. The

inlet valves as well as, in case of MDF installation, the exhaust valves have stellite-plated seat

faces and chromium-plated stems. Engines for HFO operation have Nimonic exhaust valves.

All valves are equipped with valve rotators.

A “multi-duct” casting is fitted to the cylinder head. It connects the following media with the

cylinder head:

●

charge air from the air receiver

4-2

Wärtsilä 32 Product Guide - a21 - 7 September 2016

Wärtsilä 32 Product Guide

4. Description of the Engine

Содержание WARTSILA32

Страница 18: ...This page intentionally left blank...

Страница 72: ...This page intentionally left blank...

Страница 130: ...This page intentionally left blank...

Страница 150: ...This page intentionally left blank...

Страница 186: ...This page intentionally left blank...

Страница 204: ...This page intentionally left blank...

Страница 210: ...This page intentionally left blank...

Страница 216: ...This page intentionally left blank...

Страница 238: ...This page intentionally left blank...

Страница 246: ...This page intentionally left blank...

Страница 248: ...This page intentionally left blank...

Страница 251: ......

Страница 252: ......

Страница 253: ......