7

PC 1030

GB

6

REPLACING THE STATOR

REPLACING THE STATOR

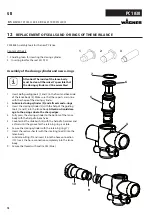

Clean the outlet unit

Clean the outlet unit (4) with a jet of water and a suitable bot-

tle brush.

Clean the container (7) with a jet of water and a suitable brush.

Clean the protective grid with a radiator brush.

Also clean the rotor (6) and stator (5) thoroughly with water

and, if necessary, using a brush.

Then spray rotor (6) and stator (5) and with a suitable pump

lubricant.

Keep the thread of the pump housing and the pump tube

clean so that leaking after the assembly is avoided.

Dismantling

Mortar spraying machine must be depres-

surised.

If necessary, set the selector switch briefly

to “R” (reverse).

Watch the manometer ––> 0 bar.

Wear safety goggles.

Disconnect external controls. Disassembly

may only be carried out by the person

who controls the machine.

Never operate mortar spraying machine

with an exposed rotor.

Do not reach into the rotor when it is mov-

ing. Risk of crushing.

Caution if you have long hair. Only wear

close-fitting clothes at work.

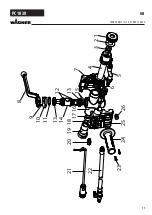

• Move selector switch (fig. 14, 1) to “A” and set delivery vol-

ume controller (2) to „0“.

•

Disconnect mains plug.

• Loosen the star screws (3) and remove the outlet unit (4).

• Set delivery volume controller (2) to 1 or 2.

•

Connect mains plug to mains power supply.

• Move the selector switch (1) to position „F“. As soon as the

stator (5) is released from the rotor (6), set the selector

switch to „A“.

• Remove the stator (5) completely.

•

Disconnect mains plug.

Mounting

If the machine is down for a longer period of

time, the stator can become set at the rotor.

Therefore, if the stator has been in storage for

a longer period of time, do not mount it until

you are about to begin work.

Assembly, see chapter 6.2.2

POWER

ERROR

SPEED

R

A

F

2

1

4

3

3

6

5

7

7

Содержание PLASTCOAT 1030

Страница 9: ...9 PC 1030 GB...

Страница 13: ...13 PC 1030 9 DRIVE ASSEMBLY PLAST COAT 1030 GB DRIVE ASSEMBLY PLAST COAT 1030...

Страница 15: ...15 PC 1030 GB...