6

PC 1030

GB

2

IMPORTANT INFORMATION ON

PRODUCT LIABILITY

An EU directive valid since 01.01.1990 specifies that the manu-

facturer is only liable for his products if all the parts originate

from the manufactured or are approved by him, and if the

units are mounted and operated properly. If accessories or

spare parts from third parties are used, liability can be partially

or completely inapplicable. In extreme cases the responsible

authorities can prohibit the use of the entire unit (German in-

dustrial employer’s liability insurance association and factory

inspectorate).

With original WAGNER accessories and spare parts, compli-

ance with all safety regulations is guaranteed.

POWER

ERROR

SPEED

R

A

F

2

1

4

3

5

TECHNICAL DATA/ REQUIRED TOOLS/ OPERATING ELEMENTS

3

TECHNICAL DATA

PlastCoat 1030

Voltage:

230 V~, 50/60 Hz

Fusing:

16 A time-lag

Device supply cable:

5 m long, 3 x 2.5 mm

2

Motor output P

1

:

2.3 kW

Max. convey capacity (water):

10, 15, 20 l/min

(depending on the rotor/

stator)

Max. operating pressure:

40 bar

Max. granular size:

K6 mm

Dimensions L x W x H:

1150 x 550 x 620 mm

Container capacity:

50 l

Weight (PlastCoat 1030):

60 kg

Weight (Spray lance):

2.1 kg

Max. tyre pressure:

2.5 bar

Degree of protection:

IP 54

Max. sound pressure level:

70 dB (A)*

Atomizing air connection:

Rapid action coupling

DN 7.2 mm

Max. atomizing air pressure:

10 bar

Minimum required compressed

air volume:

320 l/min

Max. mortar hose length:

40 m (and 2.5 m hose

whip)

Max. delivery height:

20 m

* Place of measurement: 1 m distance from unit and 1.60 m

above reverberant floor.

4

REQUIRED TOOLS AND AUXILIARY

MATERIAL

Designation

Order no.

Pump sliding means

9992824

Loctite 243

9992511

5

OPERATING ELEMENTS AND

DISPLAYS ON DEVICE

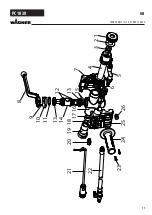

1 Delivery volume controller 0-10

2 Selector switch for operating mode

3 Indicator light (Error)

4 Operating light (Power)

5 EMERGENCY STOP switch

A

R

F

“A” position = automatic

Basic setting for control with an automatic

spray lance

A

R

F

“F” position = manual activation

Switches on the mortar spraying machine.

This setting is required for:

• disassembling the pump unit

A

R

F

“R” position = reverse gear

This setting is required for:

• relieving pressure on the mortar hose

• assembling the pump unit

Содержание PLASTCOAT 1030

Страница 9: ...9 PC 1030 GB...

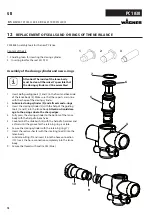

Страница 13: ...13 PC 1030 9 DRIVE ASSEMBLY PLAST COAT 1030 GB DRIVE ASSEMBLY PLAST COAT 1030...

Страница 15: ...15 PC 1030 GB...