38

Transmission

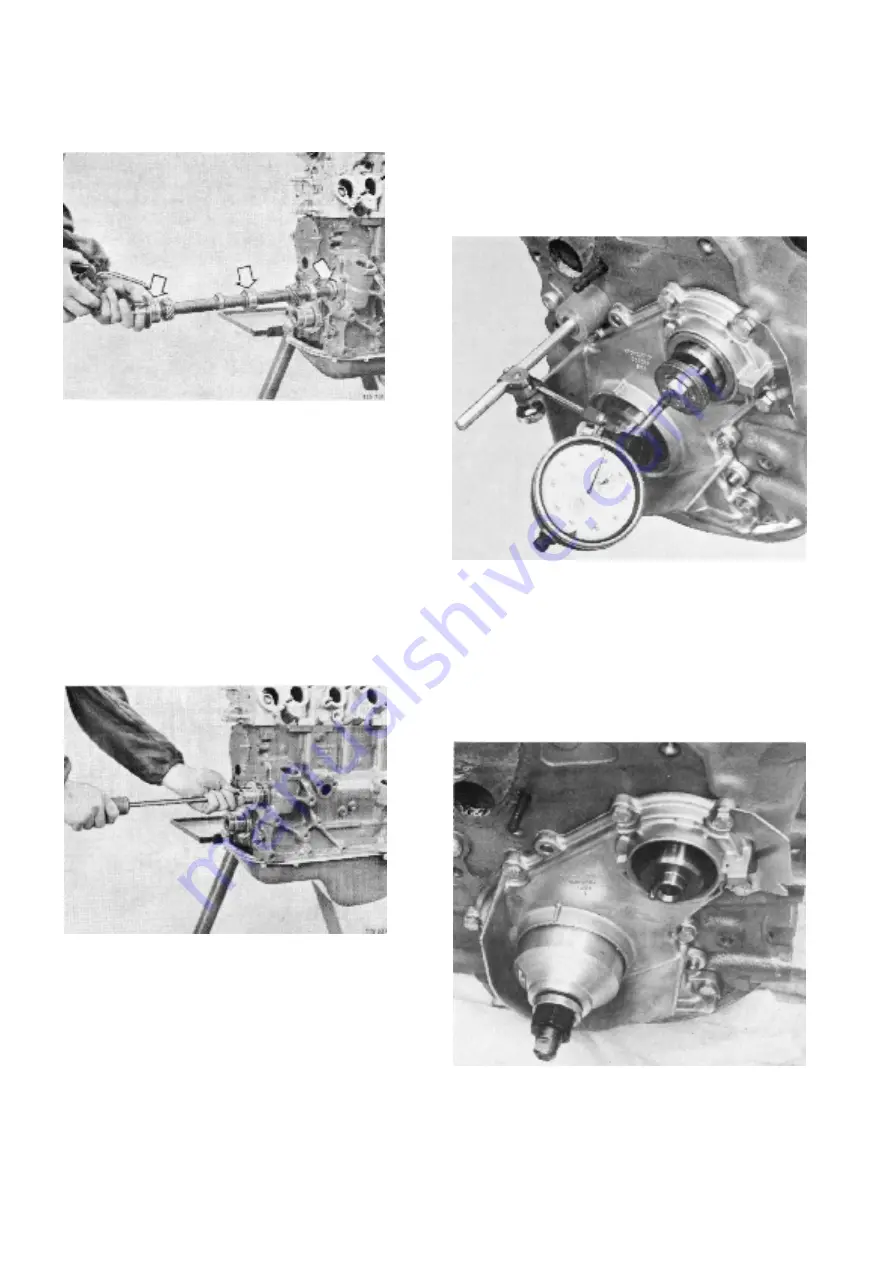

115. Oil the intermediate shaft bearings.

116. Push the intermediate shaft in carefully in the

crankcase so that the intermediate shaft’s gear

wheel does not damage the bushings in the

block. Use tool 999 4030.

117. Fit the front sealing flange (and positioning plate)

with a new gasket. The tightening torque is 10

Nm (1.0 kpm) (8.0 lbf. ft.). Then torque tighten the

screws for the sump. The tightening torque is 10

Nm (1.0 kpm) (8.0 lbf.ft.).

Then check the intermediate shaft’s axial clear-

ance. The clearance is 0.20–0.46 mm (0.0079–

0.0181 in.).

118. Fit the crankshaft seal with tool 999 5024. Lubri-

cate the seal’s rubber lip before fitting. If the spa-

cer tube on the crankshaft has not been removed

the position for the sealing ring is to be changed

so that a new contact surface against the tube is

obtained. Be careful when fitting the seal so that

the rubber lip is not damaged and that the spring

does not jump out of position.

Содержание AQ125A

Страница 1: ...Workshop Manual Engine Unit AQ125A B AQ145A B C 2 0 ...

Страница 2: ......

Страница 74: ...7739856 8 English 11 1998 ...