VMAC – Vehicle Mounted Air Compressors

Toll Free:

1-888-241-2289 Local: 1-250-740-3200

Fax: 1-250-740-3201

19

5.0 Testing Ventilation

The following procedure is recommended when a new installation

configuration is being developed. The procedure is not necessary

for repeat installations with the same configuration.

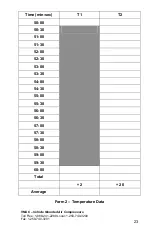

5.1 Calculating Duty Cycle

Duty cycle can be determined based on expected tool use or by

identifying the desired CFM of the system. Refer to Table 3 to

determine duty cycle from a given CFM consumption.

The rated consumption of an air tool is listed as an average based on a 25%

duty cycle. For example, a 1/2” impact might be listed by the manufacturer

as 5 CFM rather than the true consumption of 20 CFM. Do not use the

average rating in calculating duty cycle. Typical air consumption of some

pneumatic tools is:

•

1/2” impact – 20 CFM

•

3/4” impact – 30 CFM

•

Blow-off nozzle with 0.040” orifice – 2 CFM

•

Carbon arc gouger – 25 CFM

•

Pneumatic hammer – 4 CFM

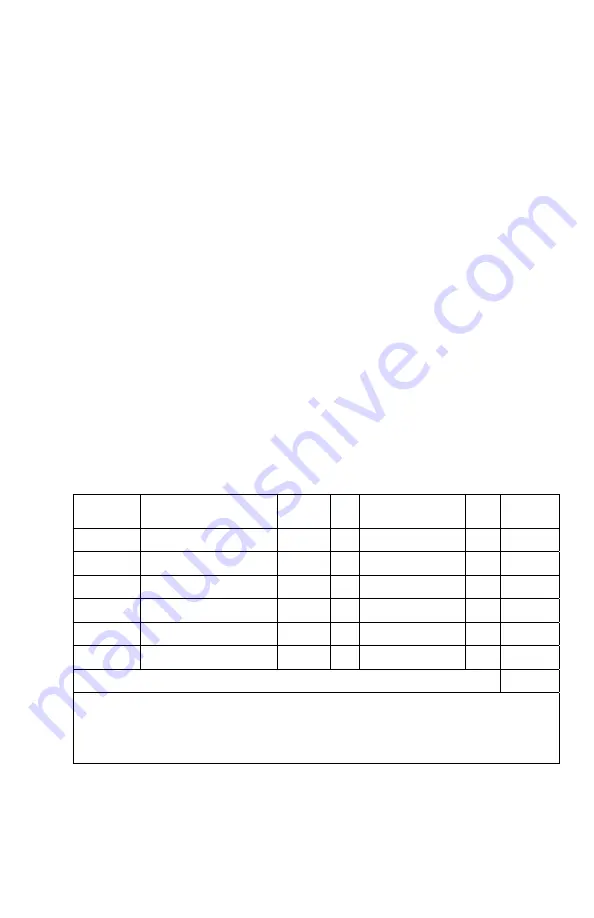

Determine what tools will be used, their actual CFM, and how many

minutes in an hour they will be used. Form 1 can be copied and used to

determine duty cycle. A sample calculation is shown in Table 2.

Tool Description

CFM

x

Operating Time

(min/hr)

= CFH

x

=

x

=

x

=

x

=

x

=

x

=

Total CFH (Cubic Feet per Hour)

Duty Cycle = Total CFH

÷

3600 x 100%

= ____

÷

3600 x 100%

= ____%

Form 1 – Duty Cycle Calculation