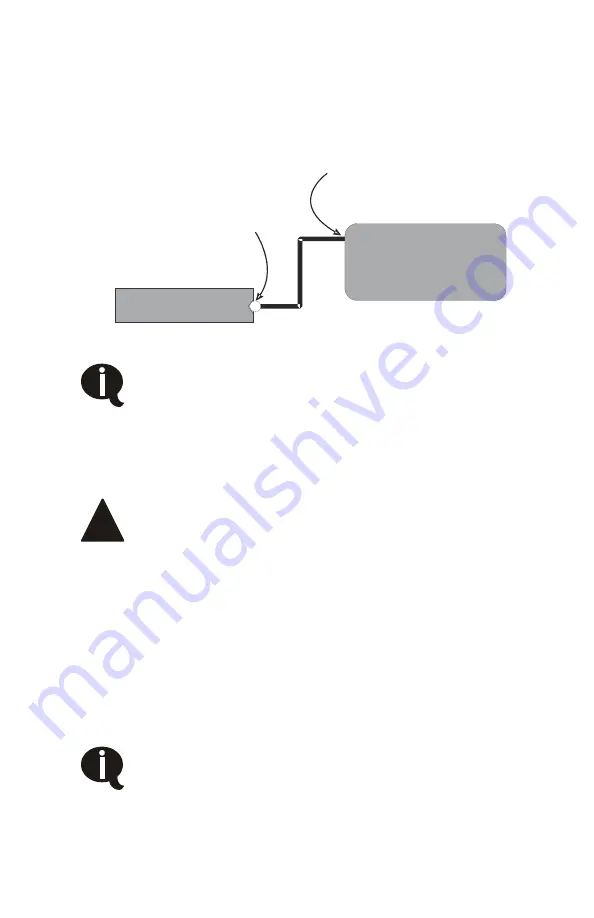

If the plumbing downstream from the PREDATAIR is tight (no leaks),

a 5 gallon air receiver is adequate. If you use an auxiliary air tank

with this system, the line to the auxiliary tank must be installed as

high as possible (not in the bottom of the tank) to prevent water from

clogging the line (Figure 3). Failure to observe these requirements

will result in damage to the system.

PREDATAIR Tank

Auxiliary Tank

One-way check valve

built into PREDATAIR

tank

Install this line high on the

tank, not at the bottom

Figure 3 – Auxiliary tank connection

A one-way check valve is built into the PREDATAIR

tank. Do not install an additional check valve as this

may cause undesirable operations.

2.2 Ventilation Requirements

During operation, the PREDATAIR can develop

considerable heat, as much as a house furnace.

!

Proper ventilation is vital for proper operation and to

avoid damage to components.

If you are installing the compressor into a new

configuration, refer to section 5.0 Testing Ventilation for

information

.

2.2.1 Top Mounting

This is the preferred mounting location. Placing the unit on top of the

service body (Figure 4) provides the best access to ambient air and

provides the best cooling. Maintain a minimum of 6” between the

sides of the compressor housing and all other solid objects

2.2.2 Enclosed Mounting

Enclosed mounting is not recommended for most

applications due to the significant heat generated.

VMAC – Vehicle Mounted Air Compressors

Toll Free:

1-888-241-2289 Local: 1-250-740-3200

Fax: 1-250-740-3201

7