□

Check the compressor and hydraulic system oil levels after the

compressor and truck engine have been shut down and the oil

level has had time to stabilize.

4.3 Setup, Performance Testing and Adjustments

This system has been adjusted at the factory for general operation. If

your tests indicate that adjustment is necessary, refer to the owner’s

manual for specific instructions on how to adjust the system.

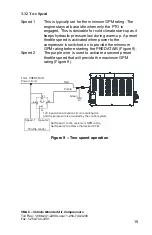

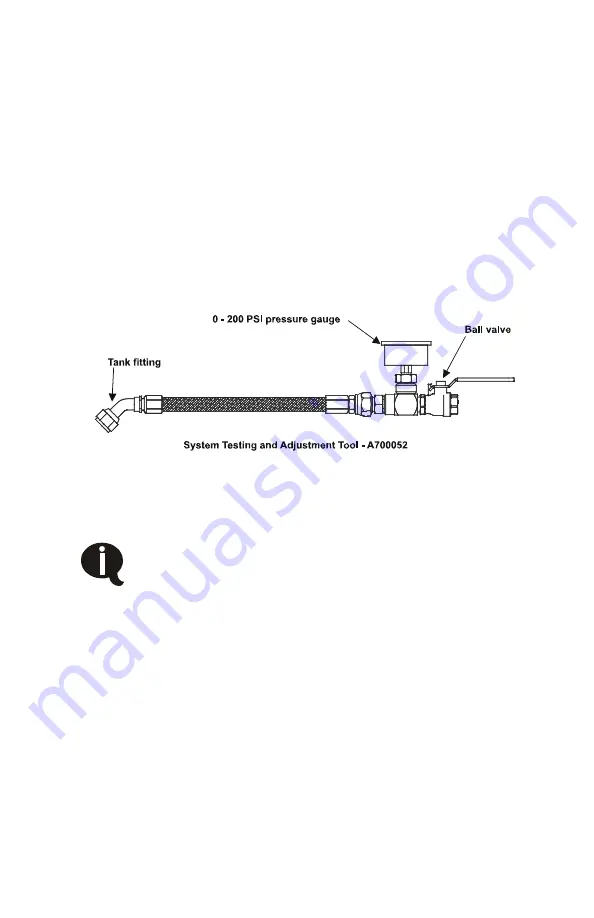

You can test the system operation using the tools that will be

operated by the system or you can test operations using an orifice

(Figure 10) to simulate tool use. See section 5.1, Table 3 to

determine the correct orifice size

Figure 10 – Test tool

1. Install the test tool in the air reservoir tank outlet fitting.

Make sure there are no leaks in the test tool. A reservoir

tank is recommended. The system may not idle down or

unload without a small reservoir of air or if there are

leaks in the lines or fittings.

2. Make sure that the ball valve is closed.

3. Place the manual transmission in neutral or the automatic

transmission in park and fully apply the park brake.

4. Allow the truck to run until the engine is at operating

temperature.

5. Operate the air compressor system until the oil is warm.

6. Observe the pressure gauge. Factory default pressure is

approximately 150 psi.

VMAC – Vehicle Mounted Air Compressors

Toll Free:

1-888-241-2289 Local: 1-250-740-3200

Fax: 1-250-740-3201

17