Technical Data

10

VITOROND 200, VD2A

Burner Calibration

Weishaupt burners / Riello burners

A Vitorond 200, VD2A boiler with a high-performance gas burner installed can achieve a

thermal efficiency of up to 85.2%, and up to 87.9% if equipped with a #2 oil burner as

follows:

Gas-fired

10% volume CO

2

, 280°F / 138°C net stack temperature, CO in ppm < 50

Oil-fired

13% volume CO

2

, 300°F / 149°C net stack temperature, smoke spot 0 - 1

(on the Bacharach Scale)

See separate instructions supplied with the burner.

The maximum input published for each boiler size must not be exceeded.

Model

Flue gas

resistance

mbar

“w.c.

VD2A-125

VD2A-160

VD2A-195

VD2A-230

VD2A-270

0.65

0.95

1.0

1.2

1.6

0.26

0.38

0.40

0.48

0.64

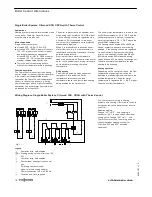

Burner manufacturer

Weishaupt or Riello

Burner/Gas train approval

Standard approvals are CSA (for Canada) and UL (for U.S.). IRI and FM approved equipment

is also available - please inquire.

Electrical requirements

Weishaupt W Series and Riello burners are available in 120 VAC, single-phase, in a 60 Hz

configuration. It is generally acceptable to use voltages within ten percent of the supply

voltage. Available voltage inside boiler room must be provided at time of order. Ensure

appropriate disconnect means and overcurrent protection.

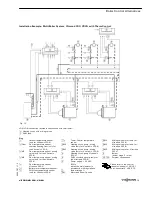

Natural gas pressure

Natural gas pressures and heating values as provided by the gas utilities vary greatly across

North America. Select the appropriate gas train accordingly. Low pressure gas trains have a

maximum input of 14 ”w.c.; high pressure gas trains have a maximum pressure of 5 psig.

Minimum gas pressures apply - please inquire. Gas pressures and heating values at site

must be provided at time of order.

5

3

5

4

7

8

7

v

1

.2