Technical Data

12

VITOROND 200, VD2A

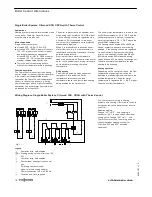

Therm-Control Low-Temperature Protection Logic

Fig. 9

A specific, matching boiler control is part of

the standard equipment of the Vitorond

200, VD2A. Boiler protection is assured by

the following:

H

Therm-Control logic

H

Control of a shunt pump

H

Flow rate reduction in the heating

circuits

H

Constant return temperature control

Therm-Control is an integrated

low-temperature protection logic provided by

the Vitotronic, GC1 control.

The control uses a Therm-Control

temperature sensor specifically positioned in

the casting close to the boiler return (shown

in Fig. 8 on page 11) to capture the thermal

state of the boiler (i.e. the temperature of

the system return mixed with the boiler

water) and react as early as possible. The

Therm-Control Logic shuts off the system

pump (and, if applicable, closes the mixing

valve) and brings the burner to full fire until

the boiler minimum setpoint temperature is

reached during start-up, preventing the

formation of flue gas condensation and

allowing for maximum heat transfer to the

system.

This ensures steady supply temperatures

with only minimal fluctuations, and

eliminates the need for a shunt pump or

return temperature elevation provided by a

Low Temperature Protection (LTP) Package.

Example:

Take a heating system with one heating

circuit and a mixing valve.

In the start-up phase, the set Therm-Control

temperature is not achieved at the

Therm-Control sensor.

The mixing valve downstream of the boiler

receives a signal via the control to reduce

the flow rate and to operate the burner at

full fire (Phase 1 shown in Fig. 9). The boiler

temperature and that captured by the

Therm-Control sensor now rapidly rise. The

mixing valve opens when the set

temperature is exceeded at the

Therm-Control sensor, and the flow rate (in

this example 50 %) inside the boiler is

steadily increased (Phase 2).

The return water temperature rises after

a certain time has elapsed which is a

function of the system water volume. As the

return temperature rises, the mixing valve

opens further until the maximum flow rate

(100%) is achieved. Now the control will

modulate the burner firing rate to achieve

the required setpoint (burner modulation),

and weather-responsive boiler water

temperature modulation will take place.

5

3

5

4

7

8

7

v

1

.2

Phase 1 -

Start-up

condition

Phase 2 -

Start-up

condition

Phase 3 -

Operating

condition

0%

flow

rate

50%

flow

rate

100%

flow

rate