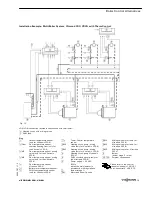

Technical Data

VITOROND 200, VD2A

11

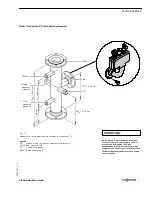

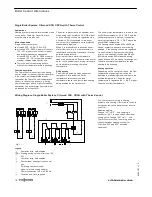

New Casting Design and Therm-Control Functionality

A specific, matching boiler control is part of the standard equipment of the Vitorond 200, VD2A.

Boiler protection is assured by the following:

- Therm-Control logic

- Control of a shunt pump

- Flow rate reduction in the heating circuits

- Constant return temperature control

The cast iron mid-sections were re-designed

to increase the heat exchanger surface area

and water volume, and the number of cast

iron sections was reduced by one section.

Together with the redesigned return water

distribution system and the Therm-Control

low-temperature protection logic, this

eliminates the need for a minimum return

water temperature.

The larger water volume and increased

width of the flue passages also ensure even

heating of the water and reduced burner

cycling.

A new tongue-and-groove system with

silicone sealant replaces the fiber-rope seal

between sections used with the VD2 Series.

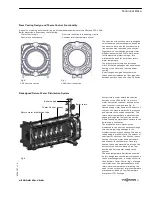

Redesigned Return Water Distribution System

System return water enters the cast iron

sections of the VD2A boiler via a return

water distribution tube now located at the

top of the cast iron block (see Fig. 8).

Heated supply water flows at the bottom of

the cast iron block towards the rear section

and upward to the supply connection. The

return water temperature is elevated when

passing through the rear cast iron section

where the supply water flows upward to the

boiler supply connection.

The pre-heated return water is then

distributed to the cast iron sections through

two upward-pointing openings in the

distribution tube at each section. The size of

the opening is proportional to the amount of

heat input of each cast iron section. In each

section the return water flows downward

and mixes with heated water. Once fully

heated, the supply water flows through the

bottom of the cast iron block up the rear

section and out the boiler supply to the

system.

The even temperature distribution ensured

by this design reduces the thermal stress on

the heat exchanger and, in conjunction with

the Vitotronic Therm-Control logic, prevents

the formation of flue gas condensate at all

return water temperatures, eliminating the

need for a shunt pump or return temperature

elevation provided by a Low Temperature

Protection (LTP) Package.

5

3

5

4

7

8

7

v

1

.2

Fig. 6

VD2 cast iron section

Fig. 7

VD2A cast iron section

Fig. 8

Boiler supply

Boiler return

Therm-Control sensor

Return water distribution tube

Fig. 8