Rev. 9/25/2017

HDC-450, MANUAL

Copyright 2017 Vestil Manufacturing Corp. Page 24 of 26

Troubleshooting Guide (HDC-DC & HDC-AC):

Contact technical support to resolve issues not addressed in this guide.

Issue

Possible Cause

Remedy

1. Pivot arm does not rise and

motor does not run

a. [HDC-DC] Low battery voltage

.

(Check

light)

b. [HDC-AC] All chassis connections to

negative post of battery not made well.

a. Recharge battery

b

.

Check and tighten or clean connections if

necessary.

2. Pivot arm does not rise but

motor is running or humming.

c.

Voltage at motor terminals might be too low

to run pump at existing load.

d. Fluid level in reservoir is low.

e. Load exceeds capacity requirements

.

Relief valve is allowing hydraulic fluid to flow

back into the reservoir

.

f. Suction filter is clogged, starving pump.

g

.

Suction line fittings are loose allowing air to

enter.

h. Filter/Breather cap on tank is clogged.

i. Lowering solenoid valve might be energized

by faulty wiring or might be stuck open

.

j

.

Hydraulic pump not operating.

c. Measure voltage at motor terminals (as near as

possible) while pump runs under load. Check for

loose wiring connections.

d

.

Add fluid. (See “Monthly inspections” and

“Yearly inspection” on p. 23 for proper fluid level

.)

e. DO NOT CHANGE RELIEF VALVE SETTING.

Instead, reduce the load to rated capacity.

f. Remove filter and clean.

g. Inspect all fittings for proper tightness.

h. Remove cap and clean

.

i.

Remove lowering solenoid valve. Check and

clean.

(Refer

to “Lowering Solenoid Valve” on p.

20.)

j. Disconnect hydraulic line from power unit. Put

pressure line in a large container and operate

the

pump. If no output

,

check the pump motor coupling

and correct as appropriate

.

If pump is worn

,

contact factory for replacement parts.

3. Pivot arm rises too slowly

.

k

.

Foreign material stuck in lowering solenoid

valve causing fluid to flow back into the

reservoir.

l. Foreign material clogging suction filter or

breather cap, or a hose is pinched.

m. Low motor voltage

.

n. Unit overloaded.

o. Inoperative pump.

k. Lower the carriage

.

Remove the lowering

solenoid valve and clean

.

(Refer to p. 20).

l

.

Correct as appropriate. (See also

,

2(f), (h)).

m

.

See 1 (b)

n

.

See 2 (e)

o. See 2 (j)

4. Motor labors or is extremely

hot.

p. [HDC-DC] Battery voltage too low.

q. Oil starvation causing pump to bind &

overheat. [NOTE: If this occurs, pump can be

permanently damaged.]

r. Binding cylinder.

p. See 1 (b)

q

.

See 2 (d), (f)

,

(g)

,

(h), (j)

r

.

Align cylinder correctly.

5

.

P

ivot arm rises in jerks or is

spongy when elevated.

s

.

Fluid starvation

.

t. Air in system

.

s

.

See 2

(d),

(f)

,

(g), (j)

t

.

See “Bleeding air from the hydraulic circuit” (p.

20).

6. Pivot arm lowers too slowly

when loaded

.

u. Lowering solenoid valve filter screen

clogged.

v. Pinched tube or hose

.

w

.

Foreign material in flow control valve.

x. Binding cylinders

.

y. Foreign material in velocity fuse.

u

.

Remove lowering solenoid valve and clean filter

screen.

v. Correct as appropriate.

w

.

Remove and clean flow control valve. Refer to

Hydraulic Circuit Diagram on p. 19)

.

x

.

Align cylinders correctly.

y. Remove and clean velocity fuse. Refer to

Hydraulic Circuit Diagram on p. 19)

.

7

.

Pivot arm lowers too quickly

.

z. Foreign material stuck in flow control valve.

(In

this case, carriage initially lowers at a

normal rate but accelerates as the carriage

descends).

z. Remove flow control valve from the valve block

and clean. (Refer to Hydraulic Circuit Diagram on

p. 19)

.

8. Pivot arm rises then slowly

lowers on its own.

aa

.

Lowering solenoid valve may be

incorrectly wired or is stuck open

bb. Check valve stuck open.

cc. Leaking hoses, fittings, pipes

.

dd

.

Cylinder packing is worn or damaged

.

aa

.

See 3 (k)

.

bb. Remove and clean check valve

.

cc. See 2 (c).

dd

.

Replace packing

(contact

factory for

replacement parts).

9. Pivot arm elevates but does

not lower

.

ee. Incorrect lowering solenoid valve wiring

.

ff

.

Lowering solenoid valve

i

s stuck.

gg. Faulty lowering solenoid coil.

ee

.

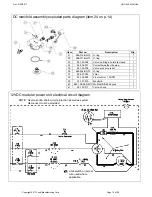

Correct per diagram (p. 15 (DC) or 18 (AC))

.

ff

.

Lightly tap down the solenoid coil body to seat it

properly

.

(DO NOT hit coil hard as it will

permanently damage the internal system

.

DO NOT

remove the solenoid valve from the block because

the

carriage will descend dangerously quickly.)

gg

.

Remove and replace. DO NOT remove the