Rev. 9/25/2017

HDC-450, MANUAL

Copyright 2017 Vestil Manufacturing Corp. Page 20 of 26

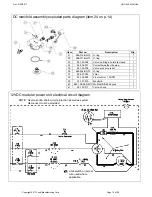

Operation of Modular Power Unit (Raising & Lowering the Pivot Arm):

The drum carriage of electrically powered units is controlled by a

handheld controller as well as pushbuttons on the power unit housing.

To raise or lower the carriage, press the appropriately marked button.

When either button is released, the carriage will maintain position.

To raise the carriage, press the

BLACK

button on the handheld

controller (or the

RAISE

pushbutton on the housing). Pressing a button

starts the electric motor which turns the hydraulic pump. Oil from the

reservoir (inside the modular power unit) flows through a suction filter

and into the pump. The pump delivers pressurized oil to the hydraulic

cylinder through a check valve. The check valve allows oil to flow only in

one direction, i.e. to the cylinders, and prevents oil from flowing back

into the pump circuit when the pump stops. This traps oil in the cylinder

allowing the carriage to maintain elevation after the control button is

released.

If a load exceeds the capacity of the lifter, pressure will build up in

the circuit between the pump and the cylinders when the

BLACK

button

is pressed. This pressure forces the relief valve to unseat which in turn

allows oil to circulate back to the reservoir rather than pushing it into the

cylinder. This pressure relief mechanism prevents damage to the

hydraulic system.

To lower the carriage, press the

WHITE

button (or

LOWER

pushbutton on the housing). This energizes the lowering solenoid valve

coil, which unseats the poppet valve and allows oil to return to the

reservoir from the cylinder through the pressure-compensated flow

control valve. Releasing the

WHITE

button de-energizes the solenoid

and closes the valve poppet. The poppet valve and check valve

together prevent oil from returning to the reservoir and cause the

cylinders to stop retracting. The carriage will maintain its position until

another command is received.

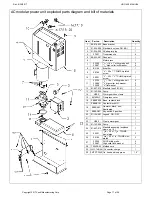

LOWERING SOLENOID VALVE

The lowering valve might occasionally need to be cleaned (see “Troubleshooting” on p. 24-25. Before working on

any

part of the hydraulic system, always lower the carriage.

1. Remove the cover from the power unit.

2. Identify the lowering valve (port LL in the manifold) and remove it.

3. Use a thin tool to press the poppet in (from the bottom of the valve) and open the valve.

4. Repeat several times while immersing the valve in kerosene or mineral spirits.

5. Blow compressed air through the valve while holding it open as described in step 3.

6. Inspect the O-rings and the PTFE washer (polytetrafluoroethylene). If either component is damaged, replace it.

7. Reinstall the valve. The valve should be tightened to approximately 20 ft.-Ib. of torque.

VELOCITY FUSE

In the base of the cylinder is a brass velocity fuse with a stainless steel spring. If a fitting begins to leak or a hose is

punctured, the pivot arm descends rapidly. If the rate of descent exceeds the preset activation speed of the velocity

fuse, the fuse closes. While the fuse is shut oil cannot flow. The pivot arm remains stationary until pressure is

reestablished.

The velocity fuse can activate although no failure occurs (e.g. air gets into the hydraulic system). To be able to

raise or lower the pivot arm requires resetting the velocity fuse. To reset the fuse, jog the pump by pushing and

releasing the

BLACK

(or

RAISE

)

button a few times. Immediately lower the carriage and disconnect the drum from

the saddle. Cycle the pivot all the way up and all the way down. Do this several times to purge air from the system.

BLEEDING AIR FROM THE HYDRAULIC CIRCUIT

If the pivot arm lowers very slowly (or not at all), air probably is trapped in the hydraulic circuit. To remove air from

the hydraulic circuit, follow these directions.

1. Lower the arm and disconnect the drum from the saddle.

2. A “bleeder” screw is located at the top of the cylinder. Loosen the bleeder screw by 1/4 to 1/2 turn to allow

trapped air to escape. Jog the motor to push air out of the system.

3. Only clear hydraulic fluid will flow from the bleeder screw opening when air has been completely removed. At

that point, reinstall the bleeder screw.

Handheld

controller

RAISE

button

LOWER

button

Modular power

unit (MPU)

Floor

lock

Pivot

arm

[Model HDC-305-60

shown]