SSI30 Wood Insert

10

63D4004

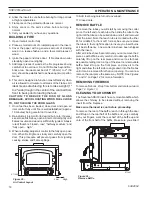

ChIMNEY ClEARANCES

It is common for a masonry flue to be oversized for the

insert. Such a chimney can take quite a while to warm up,

and the insert performance will likely be disappointing. The

best solution to an oversize flue problem is the installation

of an insulated steel chimney liner of the same diameter

as the appliance flue outlet. The liner keeps the exhaust

gas warm and the result is a stronger draft. An uninsulated

liner is a second choice—although the liner will keep the

exhaust restricted to its original volume, the air around the

liner will require time and heat energy to warm up.

Check your local codes. You may be required to install a

flue liner in any oversize masonry flue.

Masonry Chimney

Although masonry is the traditional material used for

chimney construction, it can have distinct performance

disadvantages when used to vent a controlled combustion

wood insert. Masonry forms an effective “heat sink”—that

is, it absorbs and holds heat for long periods of time.

The large mass however, may take a long time to become

hot enough to sustain a strong draft. The larger the

chimney (in total mass) the longer it will take to warm up.

Cold masonry will actually cool exhaust gases enough

to diminish draft strength. This problem is worse if the

chimney is located outside the home or if the chimney

flue has a cross-sectional volume much larger than the

insert outlet.

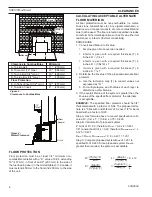

pipe and Chimney layout

Every bend in the flue will act as a brake on the exhaust

as it flows from the firebox to the chimney cap. The ideal

pipe and chimney layout is straight up from the insert

through completely straight chimney. Use this layout if at

all possible, as it will promote optimum insert performance

and simplify maintenance.

If the insertpipe must elbow to enter a chimney, locate

the elbow about midway between the inserttop and the

chimney thimble. This configuration lets the smoke speed

up before it must turn, keeps some pipe in the room for

heat transfer, and allows long-term flexibility for installing

a different appliance without relocating the thimble. There

should be no more than eight feet of single-wall insert pipe

between the insert and a chimney. Longer runs can cool

the smoke enough to cause draft and creosote problems.

Use double-wall insert pipe for longer runs.

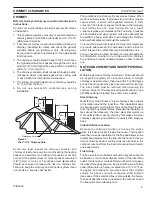

Single venting

Your insert requires a dedicated flue. Do not connect the

insert to a flue used by any other appliance. Chimney draft

is a natural form of energy and follows the path of least

resistance. If the insert is vented to a flue that also serves

open replace or another appliance, the draft will also pull

air through those avenues.

The additional airflow will lower the flue temperatures,

reduce draft strength and promote creosote development;

overall insert performance will suffer. The effect is similar to

that of a vacuum cleaner with a hole in the hose. In some

extreme instances, the other appliances can even impose

a negative draft and result in a dangerous draft reversal.