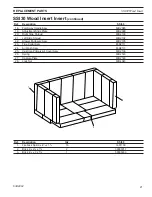

SSI30 Wood Insert

18

63D4004

OpERATION & MAINTENANCE

2. Allow the insert to cure before burning for long periods

at high temperatures.

3. Flat spots on the painted surfaces are normal.

4. Shiny spots on the paint surface before burning is

normal.

5. Call your dealer if you have any questions.

buIldINg A FIRE

1. Open inlet air control fully.

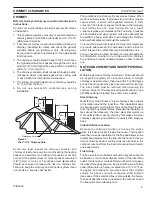

2. Place a small amount of crumpled paper in the insert.

3. Cover the paper with a generous amount of kindling

wood in a teepee fashion and a few small pieces of

wood.

4. Ignite the paper and close door. If fire dies down sub-

stantially, open door slightly.

5. Add larger pieces of wood as the fire progresses being

careful not to overload. Do not fill firebox beyond fire-

brick area. An ideal coal bed of 1" (25 mm) to 2" (50

mm) should be established to achieve optimum perfor-

mance.

6. This unit is designed to function most effectively when

air is allowed to circulate to all areas of the firebox.

An

ideal means of achieving this is to rake a slight (1"

to 2" wide) trough in the center of the coal bed from

front to back prior to loading the fuel.

CAuTION: TO REduCE ThE RISk OF glASS

bREAkAgE, AvOId lOCATINg WOOd FuEl ClOSE

TO, OR TOuChINg ThE dOOR glASS.

7. Once fuel has been loaded, close door and open air

inlet control fully until fire is well established (approx.

10 minutes) being careful not to over fire.

8. Re-adjust air inlet control to desired burn rate. If exces-

sive smoke fills firebox, open air inlet control slightly until

flames resume and wood is sufficiently ignited. A basic

rule of thumb is “closed – low,” “half way-medium,” and

“fully open – high.”

9. When refueling, adjust air control to the fully open posi-

tion. When fire brightens, slowly and carefully open the

door. This procedure will prevent gases from igniting

causing smoke and flame spillage.

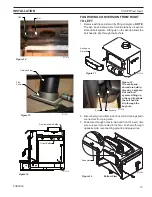

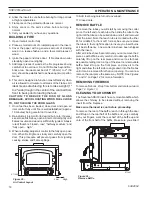

ST1087

remove baffle

ST1087

Figure 26 -

Remove Baffle

10.Add fuel being careful not to overload.

11. Close doors.

REMOvE bAFFlE

To remove the tubes you will start by removing the cotter

pin on the left end of each tube, then slide the tube to the

right until the tube can be pulled down and left and removed

from the insert. Note that each tube is marked with either

M, for middle F, for front or R for rear, be sure you replace

the tubes in there right location to insure you insert burns

at it best efficiency. 3 new cotter pins have been shipped

with the insert.

After all 3 tubes have been removed you can remove the 2

piece c-cast baffle, be very careful not to damage the baffle,

carefully lift up on the rear piece and move it as far back

as possible letting it set on top of the steel non-removable

baffle. Next lift up on the front piece and move it to the

right and allow the left side to angle down into the firebox

until it can be removed thru the door opening. You can now

remove the rear piece the same way. NOTE: See

Figures

11 and 12

on Page 12 for more information.

REMOvINg FIREbRICk

To remove firebrick, lift up from bottom and rotate outward.

Page 12, Figure 13

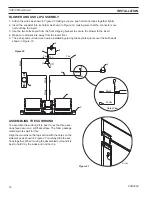

ClEANINg YOuR ChIMNEY

The Savannah SSI30 insert has a removable baffle which

allows the chimney to be cleaned without removing the

insert from the fireplace.

Make sure the insert is cool before proceeding

To remove the rear of the baffle, reach in through the door

and lift up on the rear half of the baffle and, very carefully

with your fingers, walk the rear half of the baffle up and

onto of the front half of the baffle. Make sure you slide it

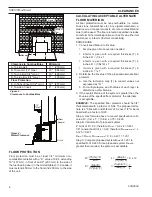

Low

High

ST1086

air control

Figure 25 -

Air Control Layout

ST1086