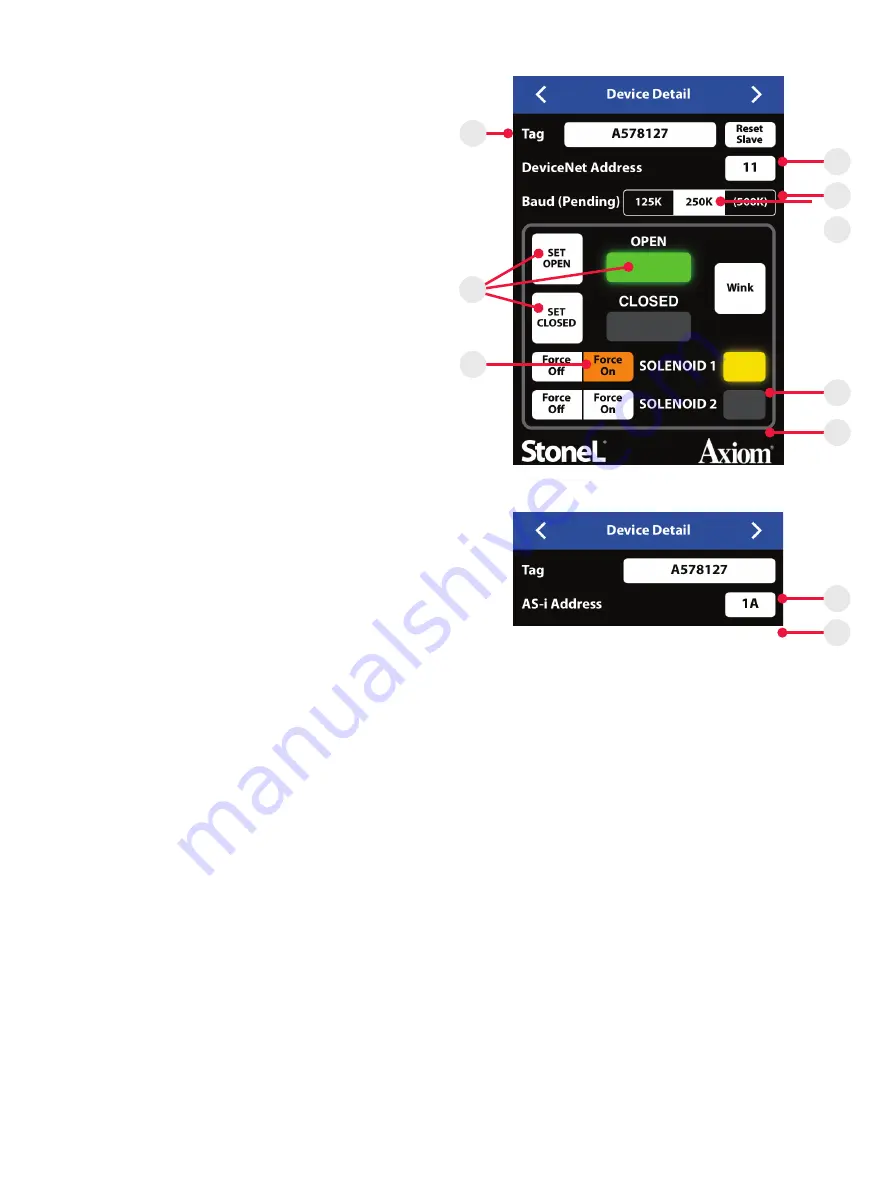

5.4 DEVICE DETAIL SCREEN

You can customize the tag for a device, change the address, change

the baud rate (if applicable), force the solenoids on or off, cause the

device to wink, and set the open/closed limits from the device detail

screen (Image 4a or 4b).

Image 4a - DeviceNet detail

Image 4b - ASi detail

E

M

K

L

J

I

G

F

N

H

Changing the device tag or address on a DeviceNet unit

1. To change the tag, edit the existing tag in the associated text field

(Item E). The tag can be up to sixteen characters long.

2. To change the DeviceNet address, edit the existing address in the

associated text field (Item G). The DeviceNet address for the 92W

can be 1 to 63

a.

When changing the address, a warning screen will appear

indicating this action could disrupt the process. Select cancel

or continue.

b.

Select continue and alter the address via number pad and

select done. A warning screen will appear indicating the

choice to reset now or reset later. Resetting the device could

disrupt the process.

c.

Selecting reset now will implement the address change of

the device.

d.

Selecting reset later will not implement device address

change until selecting reset slave (Item F) and will cause the

device address to indicate pending status.

3. To change the device baud rate (Item H), select the desired rate

from the choices. The device default baud rate is 125K.

a.

When changing the baud rate, a warning screen will appear

indicating this action could disrupt the process. Select reset

now or reset later.

b.

Selecting reset now will implement the change to the baud

rate of the device.

c.

Selecting reset later will not implement the change to the

baud rate of the device until selecting reset slave.

4. Selecting reset slave will cause a warning screen to appear

indicating resetting the device could disrupt the process. Select

continue to implement changes made to the device address and/

or device baud rate.

Changing the device tag or address on an ASi unit

1. To change the tag, edit the existing tag in the associated text field

(Item M). The tag can be up to sixteen characters long.

2. To change the AS-i address, edit the existing address in the

associated text field (Item N). The AS-i address for the 97W can

be 0A to 31A or 0B to 31B.

a.

When changing the address, a warning screen will appear

indicating this action could disrupt the process. Select cancel

or continue.

b.

Select continue and alter the address via number pad and

select done.

Forcing the solenoids on/off

Forcing a solenoid on or off will override master control if wireless link

overrides are enabled.

1. The solenoid control state is forced on or forced off when it is

highlighted in orange (Item J).

2. a. Warning screen will appear indicating this action could

disrupt the process. Select cancel or continue.

b.

Select continue and when a solenoid is on, a yellow light will

illuminate next to the solenoid (Item K).

c.

Select continue and when a solenoid is off, no light will

illuminate next to the solenoid (Item L).

Setting the valve position

Forcing the solenoid on and off is one way of actuating the valve when

setting the open and closed positions.

1. To set a valve to the closed position:

a.

Actuate the valve to the CLOSED position. This can be done

by forcing the solenoid(s) on or off.

b.

Select set closed. A warning screen will appear indicating

this action could disrupt the process. Select cancel or

continue.

c.

Select continue and the red closed light will illuminate (Item I).

d.

The valve now remembers the current position as the closed

position.

2. To set a valve to the open position:

a.

Actuate the valve to the OPEN position. This can be done by

forcing the solenoid(s) on or off.

b.

Select set open. A warning screen will appear indicating this

action could disrupt the process. Select cancel or continue.

c.

Select continue and the green open light will illuminate

(Item I).

d.

The valve now remembers the current position as the open

position.

23

EC70EN - 6/2022 | Stonel product publication 105509revA