Inspection and maintenance 9

0020233500_01 auroCOMPACT Installation and maintenance instructions

31

Note

The hot water thermostatic mixer protects against

high temperatures in the hot water installation.

The hot water from the cylinder is mixed with cold

water in the thermostatic mixer and is thereby

heated to the maximum required temperature

between 40 °C and 60 °C . The hot water ther-

mostatic mixer is set to 60 °C at the factory.

Due to energy losses in the hot water pipe, the

temperature at the draw-off points is always lower

than the temperature that is set at the thermo-

static mixer.

1

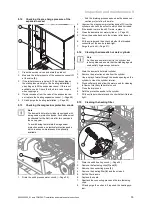

1.

Set the cylinder temperature to 65 °C and wait until this

value has been reached.

Note

Depending on the temperature setting for the

cylinder, the auxiliary heater is activated if

the solar heating is not sufficient for achiev-

ing the target temperature.

2.

Measure the hot water temperature at a draw-off point

and set the thermostatic mixer to the position that cor-

responds to the maximum temperature that is required

by the operator.

–

40 °C

(1)

–

45 °C

(2)

–

50 °C

(3)

–

55 °C

(4)

–

60 °C

(5)

3.

Then set the set target temperature for the cylinder on

the operating display.

◁

Each additional temperature boost causes unneces-

sary energy consumption.

4.

To optimise solar energy consumption in the summer,

reduce the minimum hot water temperature to 45 °C.

9

Inspection and maintenance

▶

Carry out all inspection and maintenance work in the

order shown in the table "Overview of inspection and

maintenance work".

Inspection and maintenance work

–

Overview

(

→

Page 48)

9.1

Checking the product for leak-tightness

▶

Check that the product is leak-tight. (

→

Page 27)

9.2

Observing inspection and maintenance

intervals

Proper regular inspections (once a year) and maintenance

(depending on the result of the inspection, but at least once

every two years) combined with the exclusive use of original

spare parts are decisive factors in ensuring smooth opera-

tion and long working life for the product.

We recommend taking out an inspection or maintenance

contract.

Inspection

The inspection is intended to determine the actual condition

of the product and compare it with the target condition. This

is done by measuring, checking and observing.

Maintenance

Maintenance is required in order to eliminate any deviations

of the actual condition from the target condition. This is nor-

mally done by cleaning, setting and, if necessary, replacing

individual components that are subject to wear.

Based on experience, it is not necessary to carry out annual

cleaning, e.g. on heat exchangers, under normal operating

conditions. The maintenance intervals and the scope of the

maintenance intervals are determined by the specialist in-

staller depending on the conditions on inspection. It is nev-

ertheless necessary to carry out maintenance work at least

every two years.

9.3

Procuring spare parts

The original components of the product were also certified

by the manufacturer as part of the declaration of conformity.

If you use other, non-certified or unauthorised parts during

maintenance or repair work, this may void the conformity of

the product and it will therefore no longer comply with the

applicable standards.

We strongly recommend that you use original spare parts

from the manufacturer as this guarantees fault-free and safe

operation of the product. To receive information about the

available original spare parts, contact the contact address

provided on the reverse of these instructions.

▶

If you require spare parts for maintenance or repair

work, use only the spare parts that are permitted for the

product.

9.4

Using the function menu

The function menu allows you to actuate and test individual

components in the heating installation.

Menu

→

Installer level

→

Test programs

→

Function menu

▶

Choose the heating installation components.

▶

Press (

Select

) to confirm your selection.