VAG Operation and Maintenance Instructions • 13

7.1 General safety instructions

Caution:

Prior to the performance of inspection and maintenance

work on the valve or its assemblies, shut-off the pressurised pipe-

line, depressurise it and secure it against inadvertent activation.

Depending on the type and risk of the fluid conveyed, comply

with all required safety regulations! After completing the mainte-

nance works and before resuming operation, check all connec-

tions for tightness. Perform the steps described for initial set-

up as described under Section 5 “Set-up and operation”. A VAG

EKN

®

Butterfly Valve type AWWA not equipped with a gear unit is

not self-locking. The actuator/the gear unit may not be disassem-

bled as long as the valve is pressurised. This also applies in case

the valve is completely dismantled. Statutory and local provisions

as well as the safety and accident prevention regulations must be

observed and complied with at all times. Couplings and connec-

tions must never be disassembled when they are under pressure.

Servicing, maintenance and inspection work as well as the repla-

cement of spare parts must only be done qualified staff. The plant

operator is responsible for determining the suitability of the staff

or for ensuring the relevant qualifications.

In case the operator’s employees do not have the qualifications

required, they need to attend a training course. This training

course can e.g. be held by VAG Service employees. In addition to

this, the plant operator needs to ensure that all employees have

understood these Operation and Maintenance Instructions as well

as all further instructions referred to in them. Protective equip-

ment such as safety boots, safety helmets, goggles, protective

gloves etc. must be worn during all work requiring such protective

equipment or for which such protective equipment is prescribed.

Improper or wrong use of the valve should be avoided. Prior to the

performance of any work on the valve and equipment it must be

ensured that the relevant pipeline section has been depressurised

and/or de-energised.

•

Danger:

Danger of bruise between valve body and

pipeline (-flanges) during removing the valve!

7 Maintenance and repair

Death or serious injury can result if persons remain between valve

and pipeline!

- Never stand under a suspended load!

- Lift the valve carefully until it is freely suspended.

- Avoid valve’s tilting by always moving it cautiously during lif-

ting and transport.

- Make sure that no person stays in hazardous area.

•

Danger:

Dangers from electrical current!

Death or serious injury can result when coming into

contact with energised parts.

•

Warning:

Suspended Load! All parts of the valve can tilt

and can be damaged while being lowered!

Danger of injury during lifting and transport.

7.2 Inspection and operation intervals

The valve should be checked for tightness, proper operation and

corrosion protection “at least once per year” .

In case of extreme operating conditions inspection should be per-

formed more frequently.

7.3 Maintenance work and replacement of

parts

7.3.1 Design

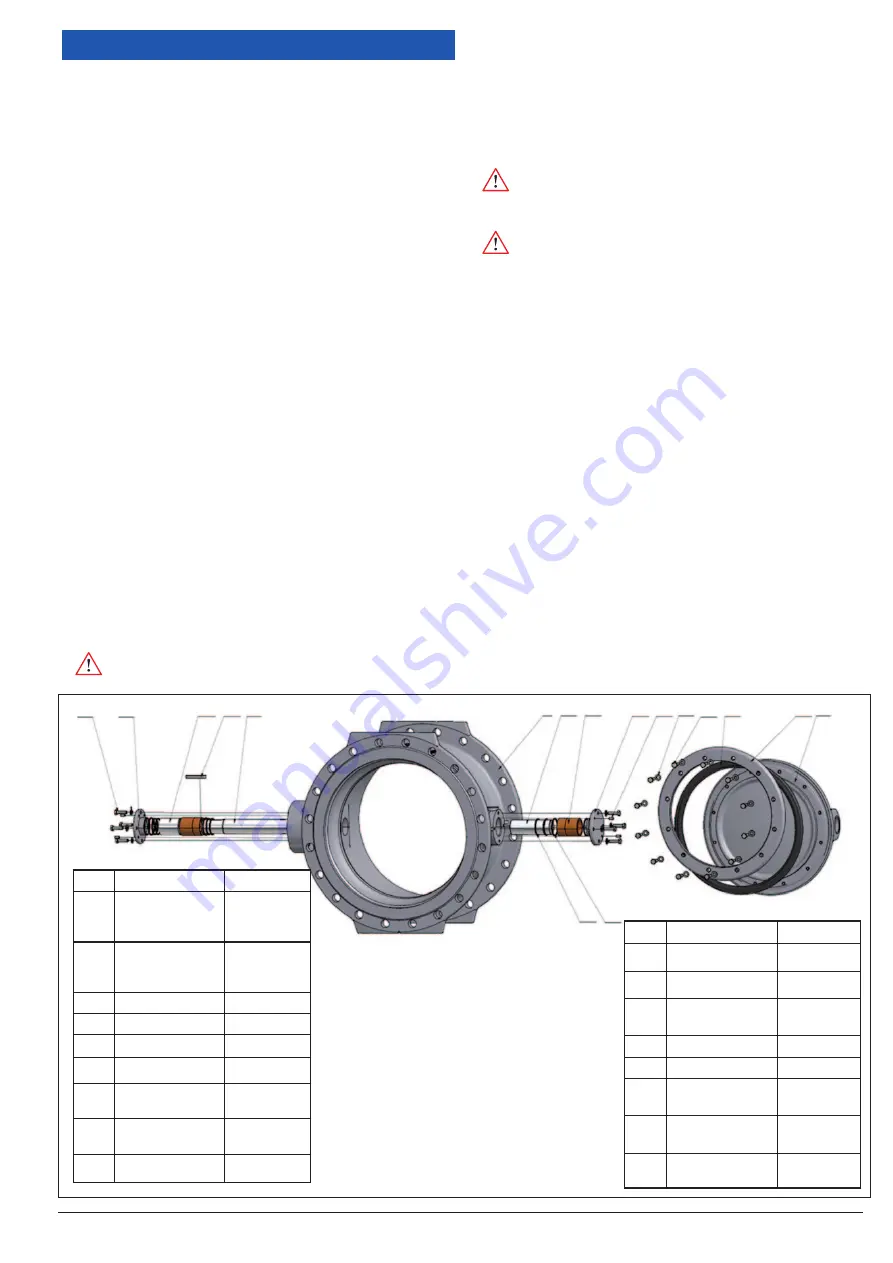

The design view in Picture 11 serves as a partial overview for the

descriptions of the working steps below.

No.

Designation

Material

1

Body

ASTM A536,

Grade 65-

45-12

2

Disk

ASTM A536,

Grade 65-

45-12

3

Profile seal

EPDM

4.1

Retaining ring

SA 105

5.1

Hexagonal screw SA 193 B8M

5.3

Washer

AISI 316

7

Shaft, driven end A276 Grade

304

8

Shaft, free end

A276 Grade

304

10

Bearing flange

A383C-A

No.

Designation

Material

11

Bearing cover

A383C-A

12

Bearing bush

C90800

13

Spacer bush

AISI 304

14

Hexagonal screw A383C-A

15

Threaded pin

A383C-A

16

O-Ring

EPDM

17

O-Ring

EPDM

20

Tapper pin

A276 Grade

431

Picture 11: Design and sub-assemblies

14

10

13

20

7

1

8

12

11

15

5.3 5.1 3

4.1 2

17

16