24

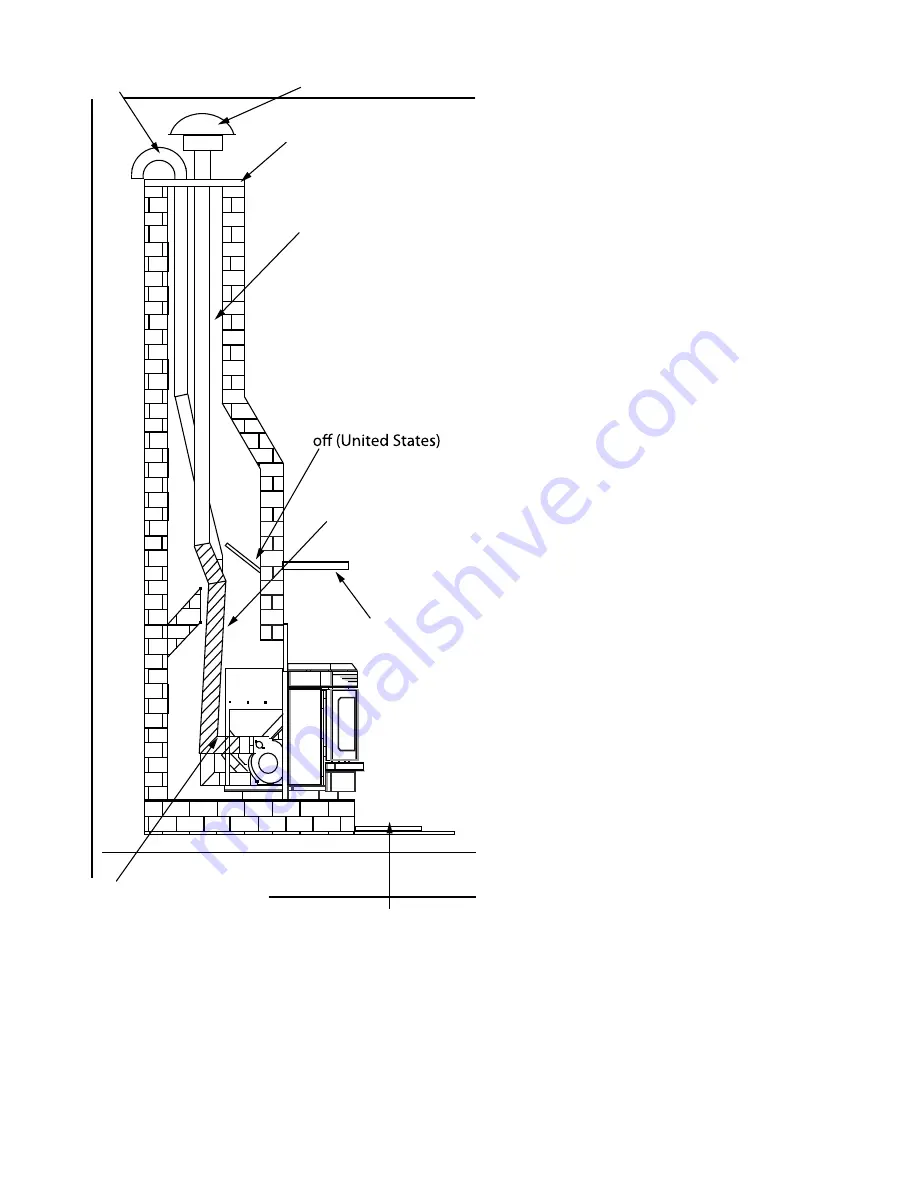

Installation into a Masonry Fireplace:

1.

Your chimney must be inspected by a certified

chimney sweep or installer to determine its structural

condition.

2.

Measure amount of venting required to top

chimney

plus 14”

to ensure the termination is adequate

distance above the roofline.

3.

The first 5’ of exhaust will be Simpson Dura Vent

pellet stove flex vent; the remainder uses rigid pipe. For

each joint subtract 1-1/2” to allow for the overlap. You

may need an adjustable length section to achieve the

correct height. The air intake may be 2” aluminum flex

vent.

4.

Assemble the first rigid section of exhaust pipe

to the flex vent pipe insuring that the “UP” arrows shown

on the pipe labels are pointing up. Connect sections

and twist to lock. Repeat the process for the remain-

der of the pipe sections and lower the assembly down

the chimney. Lower the intake and exhaust pipes be-

low their normal position to connect the pipe to back of

heater. Tie a line to the top section of venting to pull it

back up to the correct position.

5.

Connect to the exhaust of the stove by install-

ing a pipe adapter to the exhaust fan and either a 90º

elbow or a clean out tee with cap. The air intake can be

attached to the heater with a hose clamp.

6.

Connect the heater to the coupling on the bot-

tom of the exhaust flex vent and twist to the locked posi

-

tion. Push the heater into the fireplace to its final posi

-

tion.

7.

From the top of the chimney, pull the vent sys

-

tem up to the desired height.

8.

For the exhaust termination of the pellet vent

use a tall cone flashing and a storm collar. This requires

14” of pipe above the top of the masonry chimney. Pull

the pipe up through the flashing to the desired height

and mark where the storm collar will go. Slip the storm

collar down over the pipe and fasten it to the pipe with a

1/4” stainless steel sheet metal screw. The storm collar

will then support the entire exhaust vent system.

9.

Install the air intake vent through the chimney

cap by cutting a hole and install cap as shown or attach

air intake vent to a flashing and cap. The chimney top

must be properly sealed to prevent rain and or snow

from entering the chimney.

10.

Install the cap and seal around the joint of the

storm collar and any other joints that are visible.

Perform these instructions in reverse if the removal of

this appliance is ever needed for maintenance or repair.

Air Inlet

Exhaust Cap

Steel Plate or Flashing

Rigid Vent Pipe

Damper Removed or

Fastened Open

(for Canada) or sealed

Flexible Exhaust

Vent

Mantle

90º Elbow or Clean-Out Tee

Minimum 6” (150 mm)non-

combustible Floor Protection

Содержание 5560 (I)

Страница 25: ...25 VENT TERMINATION LOCATIONS Figure 22...