2

WPP 15 E | Version 1.02

Publication details

Product identification

Hydraulic workshop press

Item number

WPP 15 E

630 0016

Manufacturer

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Germany

Hotline:

0049 (0) 900 19 68 220

(0.49 Euro from German landlines)

Fax:

0049 (0) 951 - 96555-55

email: [email protected]

URL: www.unicraft.de

Information about the operating instructions

Genuine operating instructions

Edition:

24 March 2016

Version: 1.02

Language: English

Author:

DM

Copyright information

Copyright © 2016 Stürmer Maschinen GmbH, Hallstadt,

Germany.

Stürmer is the sole owner of the content of these operat-

ing instructions.

Forwarding and reproduction of this document as well

as use and notification of its content is not permitted

without explicit consent. Infringements shall oblige to

payment of compensation.

Subject to technical modifications and changes.

Contents

Publication details..................................................... 2

1 Introduction .............................................................3

1.1 Copyright ............................................................ 3

1.2 Customer service................................................ 3

1.3 Disclaimer........................................................... 3

2 Safety....................................................................... 3

2.1 Legend of symbols............................................. 3

2.2 Operator responsibility ....................................... 4

2.3 Operating staff qualification ............................... 4

2.4 Personal protective equipment........................... 5

2.5 Safety identifications on the workshop press ..... 5

3 Intended use ............................................................6

3.1 Foreseeable misuse ........................................... 6

3.2 Remaining risks .................................................. 6

4 Technical data .........................................................6

4.1 Table................................................................... 6

4.2 Environmental conditions ................................... 6

4.3 Type plate........................................................... 7

4.4 Pressure gauge .................................................. 7

5 Transport, packaging, storage...............................7

6 Machine description................................................8

7 Setup ........................................................................8

8 Installation ...............................................................8

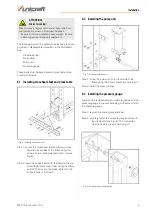

8.1 Installing the crossbeam feet and press table ... 9

8.2 Installing the pump unit ...................................... 9

8.3 Installing the pressure gauge............................. 9

9 Before commissioning..........................................10

10 Operation .............................................................10

10.1 Adjusting the table height............................... 10

10.2 Setting up the work area................................. 11

10.3 Adjusting the horizontal working position....... 11

10.4 Aligning hydraulic cylinders ........................... 11

10.5 Building up pump pressure............................ 11

10.6 Marking the cylinder limit position.................. 11

10.7 Retracting hydraulic cylinders........................ 12

10.8 Processing the workpiece .............................. 12

11 Maintenance and repairs .....................................13

11.1 Cleaning maintenance.................................... 13

11.2 Maintenance and repairs................................ 13

12 Disposal, reusing used machines.......................15

12.1 Decommissioning........................................... 15

12.2 Lubricant disposal.......................................... 15

13 Liability for defects (warranty) ...........................16

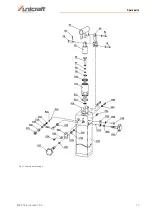

14 Spare parts...........................................................17

14.1 Spare parts orders.......................................... 17

14.2 Spare parts drawings ..................................... 18

14.3 Hydraulics circuit diagram ............................. 20

15 EU Declaration of Conformity ............................21

Содержание WPP 15 E

Страница 1: ...WPP 15 E WPP 15 E Operating instructions Hydraulic workshop press WPP 15 E...

Страница 17: ...Spare parts WPP 15 E Version 1 02 17 Fig 11 Spare parts drawing 2...

Страница 18: ...18 WPP 15 E Version 1 02 Spare parts 14 3 Hydraulics circuit diagram Fig 12 WPP 15 E hydraulics circuit diagram...

Страница 20: ...www unicraft de...