6

WPP 15 E | Version 1.02

Intended use

3 Intended use

The hydraulic workshop press is intended for use in the

automotive and mechanical engineering industry only. It

is suitable for pressing in/out bearings, bushes, em-

bossing, deformation and stamping. The capacity

stated in the technical data must not be exceeded. Do

not apply excessive force to workpieces. Check pres-

sure loads on the pressure gauge.

The hydraulic workshop press must be operated by per-

sons who have been instructed on the use of the ma-

chine only.

The intended use shall also include adherence to all in-

formation in these operating instructions. Any other use

or use beyond the intended use shall be deemed mis-

use.

Conversions at one's own responsibility or modifications

to the workshop press may invalidate the CE conformity

of the workshop press and this shall not be permitted.

Stürmer Maschinen GmbH shall not assume any liability

for design-based or technical modifications to the work-

shop press.

Unintended use of the workshop press as well as non-

observance of the safety instructions or operating in-

structions shall exclude the manufacturer's liability for

any resulting damage or injury and this shall void any

warranty claims!

Any claims resulting from damage due to unintended

use shall be excluded.

3.1 Foreseeable misuse

If the intended purpose of the workshop press is ob-

served, there is no actually foreseeable misuse that may

cause hazardous situations involving personal injury.

3.2 Remaining risks

Even when observing all safety instructions, operation of

the workshop press involves the remaining risks de-

scribed in the following.

All persons working with the workshop press must be

aware of the remaining risks and observe the instruc-

tions to prevent these remaining risks from causing ac-

cidents or damage:

- Risk of pinching upper limbs during operation

- It may be necessary to remove installed protective

equipment to configure and equip the machine.

This causes various remaining risks and potential

hazards each user must be aware of.

4 Technical data

4.1 Table

4.2 Environmental conditions

WARNING!

Risk of misuse!

Misuse of the machine may cause hazardous situa-

tions.

- Operate the machine within the performance range

stated in the technical data only.

- Do not bypass or disarm safety equipment.

- The workshop press must be operated in techni-

cally perfect condition only.

Model

WPP 15 E

Compression force

15 t

Foot width x depth

700 x 540 mm

Total height

1616 mm

Inside width

500 mm

Work area

173 - 985 mm

Piston stroke

160 mm

Piston travel

169 mm

Weight

91.5 kg

Model

WPP 15 E

Operating temperature

-5°C to 40°C

Storage temperature

-25°C to 55°C

Transport temperatures

-25°C to 70°C (< 24 h)

Altitude range

max. 1,000 m

Humidity

max. 85% relative hu-

midity

Working environment

Non-flammable, dry and

free from dust

Содержание WPP 15 E

Страница 1: ...WPP 15 E WPP 15 E Operating instructions Hydraulic workshop press WPP 15 E...

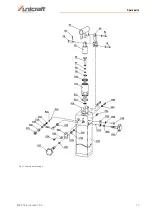

Страница 17: ...Spare parts WPP 15 E Version 1 02 17 Fig 11 Spare parts drawing 2...

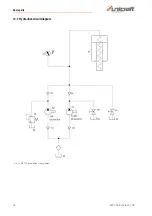

Страница 18: ...18 WPP 15 E Version 1 02 Spare parts 14 3 Hydraulics circuit diagram Fig 12 WPP 15 E hydraulics circuit diagram...

Страница 20: ...www unicraft de...