10

WPP 15 E | Version 1.02

Before commissioning

9 Before commissioning

Step 1: bleed the hydraulic system; for this purpose,

turn the switching valve in anti-clockwise direc-

tion. Operate the pump lever several times to re-

move the air from the hydraulic system. Then

once again close the switching valve.

Step 2: check all lines and connections are not leaking.

Check all machine parts are undamaged and

operate as intended.

10 Operation

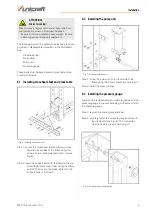

10.1 Adjusting the table height

Adjust the correct table working height using the sup-

port bolts to safely work on the hydraulic workshop

press.

Step 1: lift the press table on one side and keep it in this

position.

Step 2: pull the support bolt from the frame bore on the

side the table was lifted.

Step 3: lift the press table to the desired height or

slightly above the corresponding frame bore.

Step 4: insert the support bolt into the corresponding

frame bore.

Step 5: lower the press table onto the support bolt.

Step 6: also carry out these steps on the second side so

the table is positioned horizontally.

10.2 Setting up the work area

The work area must have been set up properly to be

able to safely process the workpiece.

WARNING!

Risk of death!

Non-observance of these instructions causes a risk

of death.

- Do not work on the hydraulic workshop press under

the influence of alcohol, drugs or medication and/

or if you are very tired or suffer from conditions im-

pairing your concentration.

- The hydraulic workshop press must be operated by

one person only. Additional persons must keep out

of the work area during operation.

ATTENTION!

Risk of pinching!

Incorrectly working on the hydraulic workshop press

causes a risk of injury to fingers and hands.

- Securely position the workpiece for processing on

the support blocks and/or secure it to the support

blocks.

- Do not reach into the operating range of the hy-

draulic workshop press during operation.

- Do not reach into the press and keep away from

moving parts!

Wear head protection!

Wear hearing protection!

Wear protective goggles!

Wear protective gloves!

Wear safety shoes!

Wear protective clothing!

NOTE!

Carry out the following before operating the hydrau-

lic workshop press for the first time.

- Check all screw connections on the installed, hy-

draulic workshop press and retighten if necessary.

- Fill the pump with hydraulic oil or top it up and seal

the filler neck using the yellow, plastic vent plug.

- Remove any air from the hydraulic system.

ATTENTION!

Risk of pinching!

Pinching may result from the press table not having

been fully supported on the support bolts.

- Check the table is fully supported on the support

bolts before adjusting the table height.

- Make sure the safety splints have been attached

correctly!

Содержание WPP 15 E

Страница 1: ...WPP 15 E WPP 15 E Operating instructions Hydraulic workshop press WPP 15 E...

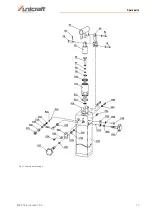

Страница 17: ...Spare parts WPP 15 E Version 1 02 17 Fig 11 Spare parts drawing 2...

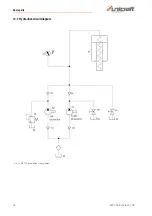

Страница 18: ...18 WPP 15 E Version 1 02 Spare parts 14 3 Hydraulics circuit diagram Fig 12 WPP 15 E hydraulics circuit diagram...

Страница 20: ...www unicraft de...