- 20 -

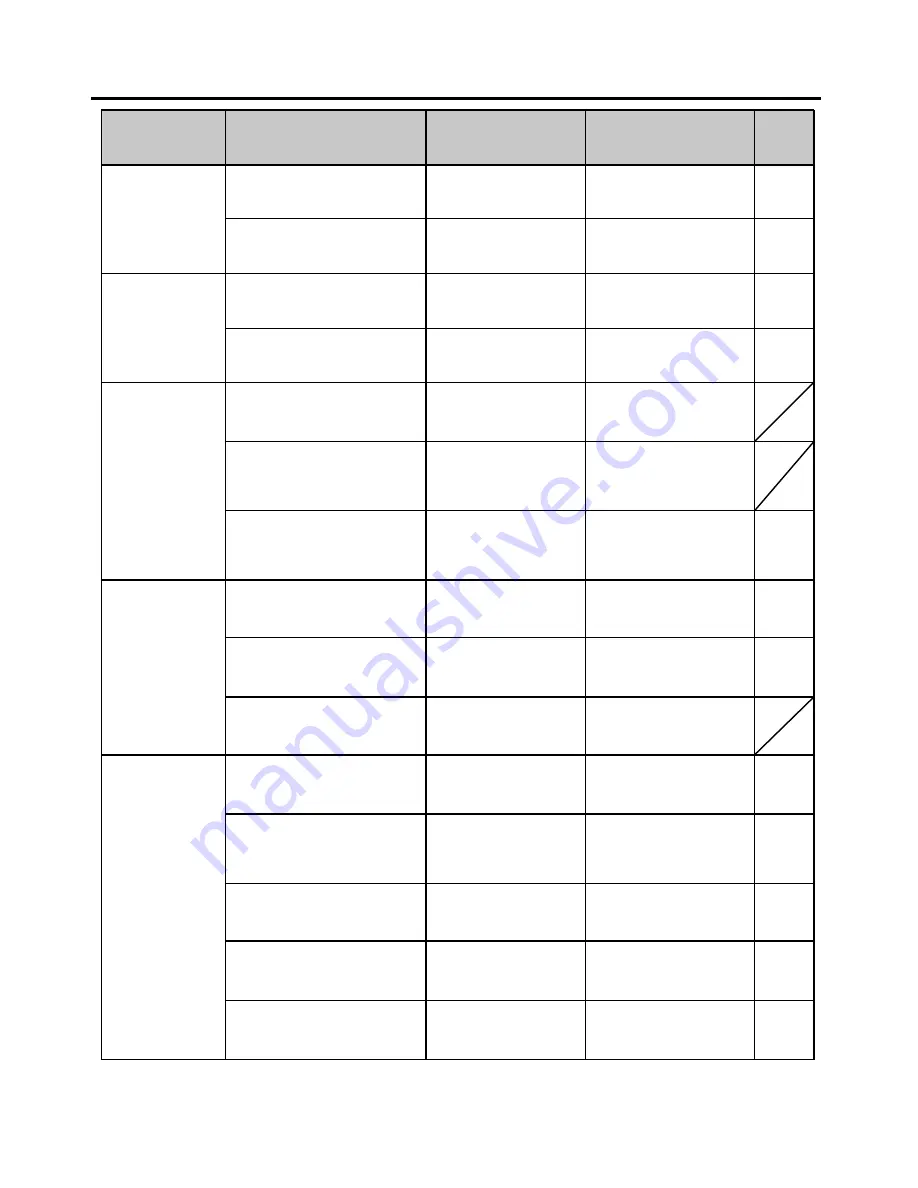

조정 개소의 보기

현 상

원 인

점 검

처리

․

대책

페이지

윗실이 죄이지

않는다

윗실 장력이 너무 약하다

―

윗실 장력을 강하게

한다

6

밑실 장력이 너무 강하다

―

밑실 장력을 강하게

한다

6

밑실이 죄이지

않는다

윗실 장력이 너무 약하다

―

윗실 장력을 약하게

한다

6

밑실 장력이 너무 강하다

―

밑실 장력을 강하게

한다

6

타오루눈 등의

죄임 불량

실 지나는 길의 마무리가

나쁘다

각 실 지나는 길의

확인

퍼프(puff) 등으로

닦는다

보빈의 미끄럼 불량

밑실을 잡아당겨, 실

의

장력을 확인한다

보빈을 교환한다

가마를 교환한다

가마와 가마고정의 간격이

작다

가마고정의 간격을

확인한다

[바늘과 가마의 타이

밍

조정]을 한다

8

윗밑실 모두

잘리지 않는다

이동칼과 고정칼이 맞물려

있지 않다

―

이동칼과 고정칼을

맞물리게 한다

11

이동칼

․

고정칼의 날부분의

상처마모

이동칼

․

고정칼의

날부분

이동칼과 고정칼의

교환

14

이동칼이 움직이지 않는다 사절신호가 나오는가

전기회로의 점검

사절솔레노이드 교환

윗실이 잘리지

않는다

밑실이 잘리지

않는다

바늘의 설치방법이 나쁘다 바늘의 방향

바늘을 올바르게

설치한다

4

최종땀에서 봉비되고,

이동칼이 윗실을 잡지 못

한다

침하정지위치를

확인한다

침하정지위치의 조정

13

이동칼과 고정칼이 맞물려

있지 않다

―

이동칼과 고정칼을

맞물리게 한다

11

이동칼과 고정칼의 잘림이

나쁘다

이동칼

․

고정칼의

날부분

이동칼과 고정칼의 교

환

14

이동칼과 고정칼이 맞물려

있지 않다

―

이동칼과 고정칼을

맞물리게 한다

11

Содержание LS2-H530

Страница 2: ......

Страница 4: ...5 off A S 34 2 40 25 OFF A S A S...

Страница 26: ...16 4 4 8 8 8 8 4 4 4 6 6 6 2...

Страница 28: ...18 4 4 1 4 4 8 8 8 6 6...

Страница 30: ...20 6 6 6 6 puff 8 11 14 4 13 11 14 11...

Страница 32: ...22 6 1 13 6 11 11 11 11...

Страница 34: ...24...