- 11 -

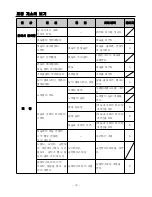

6. 이동칼과 고정칼의 위치조정 / Adjusting the movable and fixed knives

조 정 / ADJUSTMENT

★ 사절캠에 사절캠레버(조)의 고로축이 올라갔을 때 이동칼①과 고정칼②의 날 부분의 맞물리는 양이

약1mm로 되어있는 것을 확인해주십시오.

1. 미싱풀리를 돌리고 침봉은 최하위치에서 5mm상승시켜주십시오.

2. 사절솔레노이드③을 손으로 누르면 사절캠④의 홈부에 고로축이 들어갑니다.

3. 사절솔레노이드③을 누른 채로 미싱풀리를 돌리고 사절캠④에 고로축이 들어갔을 때, 이동칼① 고정칼②의 날 부분을

맞춰주십시오.

4. 죔나사⑤을 풀고, 사절레버⑥을 이동시켜, 이동칼①이 고정칼②의 날 부분에 1mm 맞물리도록 조정해주십시오.

이때, 사절홀다⑦의 위치점과 사절홀다누름⑧의 위치점이 만납니다.

5. 조정 후, 죔나사⑤을 확실히 체결해주십시오.

※ 실처리⑨은 반드시 이동칼①의 아래에 설치해주십시오.

★ Check that the overlap of the movable knife ① and the fixed knife ② is approx. 1 mm when the

rotation of thread trimming clutch ④ has lifted the roller shaft of the thread trimming cam lever

assembly to its farthest extent.

1. Turn the machine pulley so that the needle bar is 0.5 mm above its lowest position.

2. Depress the thread trimmer solenoid ③ manually so that the roller shaft fits in the indentation of the

thread trimming clutch ④.

3. With the thread trimming solenoid ③ depressed, turn the machine pulley. Adjust the movable knife

① and the fixed knife ② so that they overlap when the rotation of thread trimming clutch ④ has

lifted the roller shaft of the thread trimming cam lever assembly to its farthest extent.

4. Loosen the screw ⑤ and move the thread trimmer lever ⑥. Adjust the overlap of the movable

knife ① and the fixed knife ② to 1 mm. At this time, the index marks of the thread trimming

holder ⑦ and the notch of the thread trimming holder support ⑧ should align.

5. Tighten the screw ⑤.

※ Make sure that the lower thread finger ⑨ is attached under the movable knife ①.

Содержание LS2-H530

Страница 2: ......

Страница 4: ...5 off A S 34 2 40 25 OFF A S A S...

Страница 26: ...16 4 4 8 8 8 8 4 4 4 6 6 6 2...

Страница 28: ...18 4 4 1 4 4 8 8 8 6 6...

Страница 30: ...20 6 6 6 6 puff 8 11 14 4 13 11 14 11...

Страница 32: ...22 6 1 13 6 11 11 11 11...

Страница 34: ...24...