- 12 -

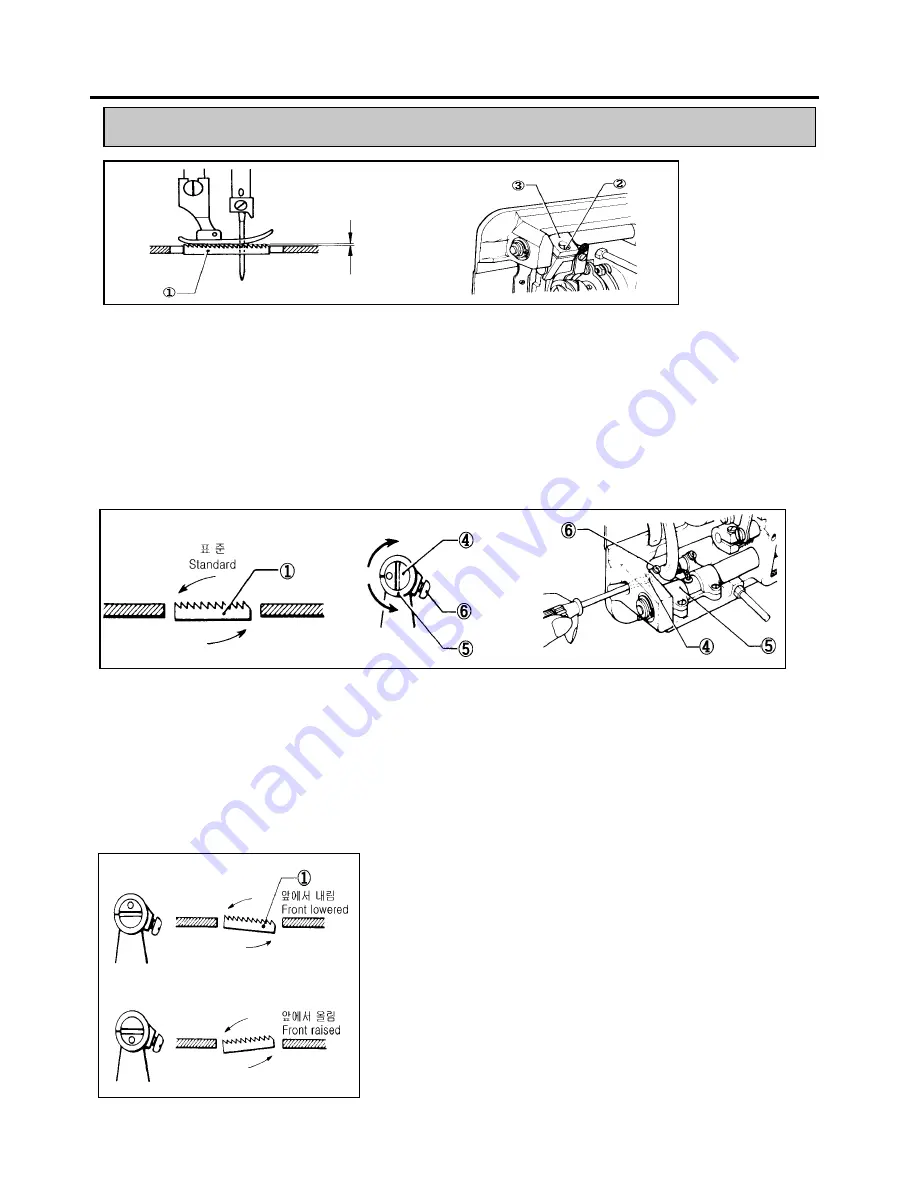

7. 톱니 높이 조정 / Adjusting the feed dog height and angle

조 정 / ADJUSTMENT

ꁴ

톱니의 높이조정 / Feed dog height

1. 톱니①이 침판상면에서 최대한 올라갔을 때의 표준높이는, 박물용

․

중후물용에서 0.8mm, 후물용에서 1.2mm입니다.

2. 톱니①이 침판상면에서 최대한 올라갔을 때, 죔나사②를 풀고, 상하이송아암③을 돌리고, 이송대를 상하 움직여

조절해주십시오.

1. The feed dog height should be 0.8 mm for thin and medium materials, and 1.2 mm for thick

materials, when the feed dog ① is fully raised.

2. To adjust the feed dog height, loosen the screw ② with the feed dog ① fully raised, and then

rotate the feed lifting crank ③ to move the feed bracket up or down.

ꁴ

톱니의 경사조정

1. 톱니①이 침판상면에서 최대한 올라갔을 때, 표준경사는 이송대축④의 ○표시와 수평이송아암⑤의 표시가 일치합니다.

2. 톱니①의 경사를 조정하는 경우는, 2개의 고정나사⑥을 풀고, 이송대축④을 표준위치에 대해서 화살표 방향으로 90°범위

내에서 조정해주십시오.

1. When the feed dog ① is fully raised, its angle is properly adjusted if the circle on the feed bracket

shaft ④ aligns with the index on the feed rock shaft arm ⑤.

2. To adjust the feed dog ① angle, loosen the two screws ⑥ and then rotate the feed bracket shaft

④ within 90° in the directions indicated by the arrows.

3. 파카링을 방지하기 위해서는 톱니①의 경사를 앞쪽이 내려

가도록 해주십시오.

4. 천 벗어남(재봉 어긋남)을 방지하기 위해서는 톱니①의 경사를 앞쪽이

올라가도록 해주십시오.

주) 톱니①의 경사를 조절하면 톱니①의 높이가 변하기 때문에 다시

톱니①의 높이를 조정해주십시오.

3. To prevent puckering, lower the front of the feed dog ①.

4. To prevent materials from slipping, raise the front of the feed

dog ①.

※ After adjusting the feed dog ① angle, be sure to adjust

the height of the feed dog.

Содержание LS2-H530

Страница 2: ......

Страница 4: ...5 off A S 34 2 40 25 OFF A S A S...

Страница 26: ...16 4 4 8 8 8 8 4 4 4 6 6 6 2...

Страница 28: ...18 4 4 1 4 4 8 8 8 6 6...

Страница 30: ...20 6 6 6 6 puff 8 11 14 4 13 11 14 11...

Страница 32: ...22 6 1 13 6 11 11 11 11...

Страница 34: ...24...