36 UNIBLOC-PD Operation & Service Manual: PD200-576

PROBLEM

POSSIBLE CAUSE

SOLUTION

E. Pump is noisy

1. Cavitation.

2. Liquid contains air.

3. Discharge pressure too high.

1. See C.

2. Check pump shaft seals for

leaks. Check suction side pipe fit

-

tings for leaks. Increase NPSHA.

3. Check suction and discharge pip-

ing for closed valves or obstruc-

tions. Increase pump size.

F. Motor overheating

1. Motor size too small.

2. Discharge pressure too high.

3. Viscosity higher than

expected.

4. Motor & pump misalignment.

1. Increase motor size.

2. Lower pump speed. Lower

pressure. Check suction and

discharge piping for closed valves

or obstructions.

3. Decrease pump speed. Increase

pipe size or shorten discharge

pipe length.

4. Correct alignment.

G. Shaft seals leak

1. Loose drive collar on single

mechanical seals.

2. Worn parts.

3. Seals have been operated

without product in pump or with-

out flushing liquid.

4. Seal incompatible with liquid

1. Reset drive collars.

2. Replace seals and/or o-rings.

3. Operate pump only when liquids

Can come in contact with seals.

Replace worn seal parts.

4. Contact factory for proper seal

selection, operation, and replace

if necessary.

Содержание 54001010P20H6010T12E

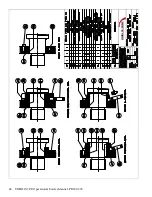

Страница 42: ...42 UNIBLOC PD Operation Service Manual PD200 576 UNIBLOC PUMP ...

Страница 43: ...UNIBLOC PD Operation Service Manual PD200 576 43 UNIBLOC PUMP ...

Страница 44: ...44 UNIBLOC PD Operation Service Manual PD200 576 UNIBLOC PUMP ...

Страница 45: ...UNIBLOC PD Operation Service Manual PD200 576 45 UNIBLOC PUMP ...

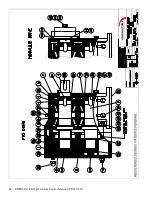

Страница 46: ...46 UNIBLOC PD Operation Service Manual PD200 576 UNIBLOC PUMP ...

Страница 47: ...UNIBLOC PD Operation Service Manual PD200 576 47 UNIBLOC PUMP ...

Страница 48: ...48 UNIBLOC PD Operation Service Manual PD200 576 UNIBLOC PUMP ...

Страница 49: ...UNIBLOC PD Operation Service Manual PD200 576 49 UNIBLOC PUMP ...

Страница 50: ...50 UNIBLOC PD Operation Service Manual PD200 576 3 ...

Страница 51: ......

Страница 52: ......