5

INSTALLATION AND OPERATION MANUAL

inform the user on how to use the heating

system and provide technical documenta-

tion for the appliances used in the installa-

tion. The installer must fill in:

• Heating system booklet

• Documentation for the installation

The technical documentation includes:

• Reference to the current standards;

• Manufacturers installation indications;

• A rough description or scheme, or photo-

graphs of any system modifications made;

• Compliance Certificate;

• The date and the installer’s signature.

A sign upon receipt of the technical

documentation is requested from the

user.

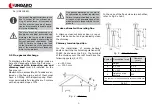

3.3 Installation Area

The stove should be positioned on the fire

resistant floor. If the flooring is made of

flammable material, provide a floor pro-

tection surface in compliance with current

national standards. Respect the safety cle-

arance as shown on fig. 2.

Ungaro S.r.l. will not accept any

liability in case of fire for failure to

comply with the safety clearance.

C

A

B

Flammable

Materials

Non flammable

Materials

A

500 mm

200 mm

B

500 mm

200 mm

C

1500 mm

1500 mm

fig. 2 - Safety clearance

3.4 Heating and ductable air fans

The stove has two fans for forced air he-

ating. The standard configuration for both

fans is frontal outlet, heating the room of

installation. According to the factory stan-

dard, the upper fan can be used for ducta-

ble air heating in the remote room. The fan

can be spinned positioning the hot air outlet

backwards, see the precut indicated on the

fig.3. Then must the ductable ait function

must be activated in the control panel. This

modification can be made only by an au-

thorized technician. It’s recommended to

bring the ductable air pipe not longer than

8 linear meters in a single destination.

D

uc

table air outlet N 1

D

uc

table air outlet N 2

Smoke outlet

Pr

imar

y air en

tr

anc

e

412,5

133

245

136

267

261

1118,5

128,5

fig. 3 - Ductable air outlets

3.4 Flue Pipe

(ref. UNI 10683)

The flue pipe must meet the following re-

quirements:

• Twin wall steel flue, required diameter

is 100 mm round;

• It must be resistant to heat, mechani-

cal stress, heat, combustion residues

and related condensate;

• It must be installed at a safe distance

from eventual combustible materials;

• It must have draft between 11 and 15