YK11-0016-DI-002-08

1

1. For Your Safety Use

1.1 This Product Intrinsic Hazardous Nature and Safety Measures

Before operating or checking this machine, thoroughly read this paragraph, and after fully

understanding about latent danger and on how to avoid danger, perform the work.

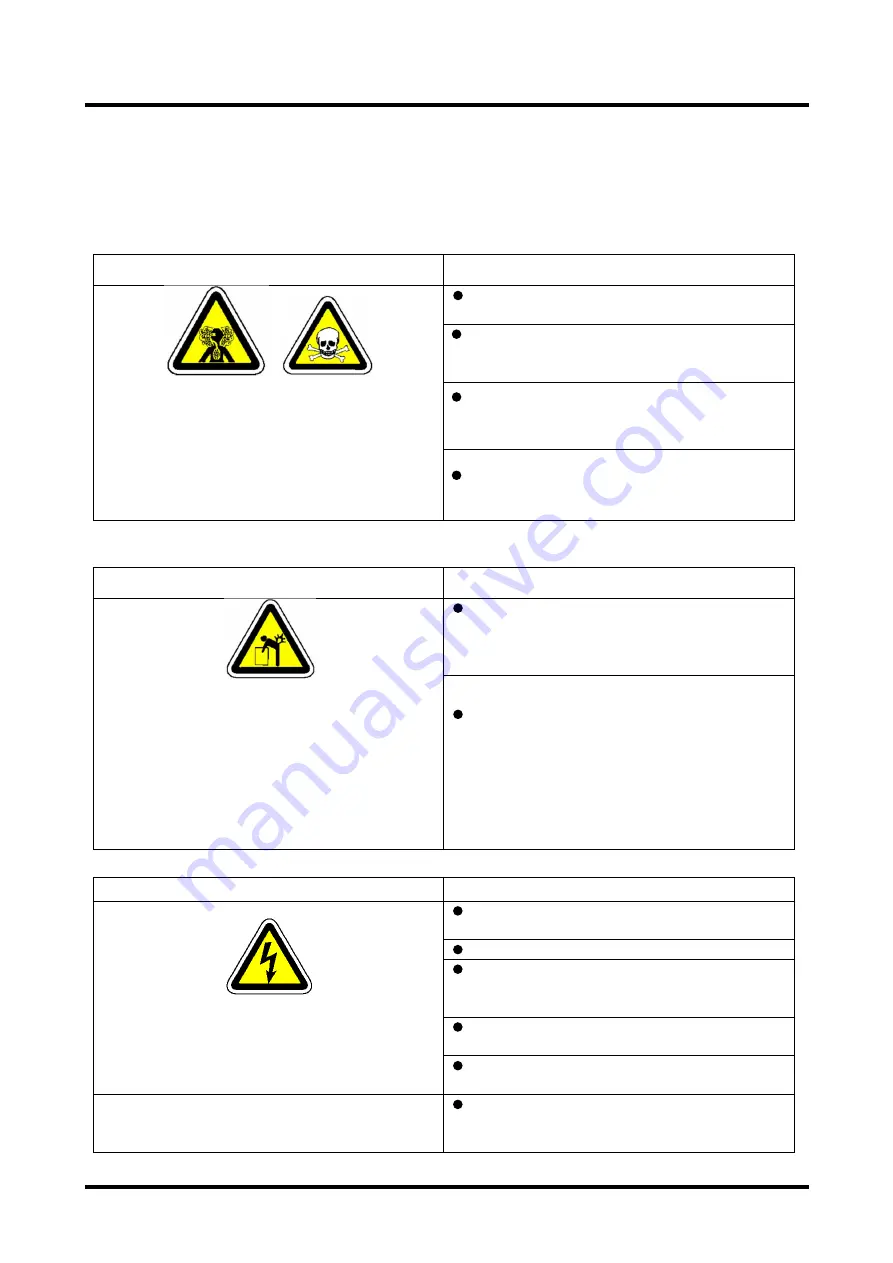

1.1.1 ! Danger Leakage of dangerous gas and dangerous materials

Factors

Avoidance methods and measures

Leakage of poisonous and combustible

gas

Getting injured on touching any toxic

pump oil, pump, generated material or

sucked substance at the occasion of

check or disposal.

Do not exhaust any hazardous gas

such as toxic and combustible.

When you check the pump, please

wear a brace that supports the toxic

substances that exhaust the pump.

To overhaul or dispose,

ask the special agency to do the

detoxification process.

Ask the disposal agency licensed by

the administration for disposal.

1.1.2 ! Warning Transfer of heavy material

Factors

Avoidance methods and measures

Getting injured on

transferring

the pump

Pump weight

PMB100D

:

26kg

PMB300D

:

51kg

PMB600D

:

82kg

PMB1200D

:

115kg

PMB2400D

:

260kg

Only technically entitled person

should

be

in

charge

of

loading/unloading

and

operating

machines.

There is a risk that the Pump might

drop or lay down when attempted

unreasonable operation or machinery

setup was not sufficient.

You are strictly restricted from entering

beneath the Pump.

1.1.3 ! Warning Electric shock

Factors

Avoidance methods and measures

Getting electrical shock

on touching the

current-carrying part of

the motor.

Be sure to cut the electricity to do

electrical connection.

Never fail to take the earth connection.

Ensure to close the cover of motor

terminal box and never open it during

operation.

Be sure to cut the electricity to do

checking or installation.

Never attempt to put in the hand or bar

into the opening of the Motor.

Motor terminal mount

gets burnt.

Tighten close the terminal.

Check the tightening once a month.

(Refer to “3.5 Electrical Connection”)

Содержание PMB100D

Страница 2: ......

Страница 3: ...Declaration of Conformity...

Страница 39: ...YK11 0016 DI 002 08 12 2 4 Dimensional drawing Fig 11 Dimensional drawing PMB100D...

Страница 40: ...YK11 0016 DI 002 08 13 Fig 12 Dimensional drawing PMB300D...

Страница 41: ...YK11 0016 DI 002 08 14 Fig 13 Dimensional drawing PMB600D...

Страница 42: ...YK11 0016 DI 002 08 15 Fig 14 Dimensional drawing PMB1200D...

Страница 43: ...YK11 0016 DI 002 08 16 Fig 15 Dimensional drawing PMB2400D...

Страница 62: ...YK11 0016 DI 002 08 35...

Страница 65: ...YK11 0016 DI 002 08 38...

Страница 72: ...YK11 0016 DI 002 08 45...

Страница 83: ...YK11 0016 DI 002 08 56 5 7 Optional attachment figure Fig 27 PMB100D Optional attachment figure...

Страница 84: ...YK11 0016 DI 002 08 57 Fig 28 PMB300D Optional attachment figure...

Страница 85: ...YK11 0016 DI 002 08 58 Fig 29 PMB600D Optional attachment figure...

Страница 86: ...YK11 0016 DI 002 08 59 Fig 30 PMB1200D Optional attachment figure...

Страница 88: ...YK11 0016 DI 002 08 61 Fig 32 PMB2400D Optional attachment figure If you have installed the inlet ISO K flange...

Страница 89: ...YK11 0016 DI 002 08 62 Fig 33 Dimensional drawing PMB2400D Horizontal exhaust model...

Страница 99: ...YK11 0016 DI 002 08 72...

Страница 105: ...YK11 0016 DI 002 08 78...

Страница 119: ......