- 6 -

3. Installation

3.1 Installation

The pump should be installed on a level surface in a location with minimal dust, dirt and

humidity and be arranged with consideration given to ease of installation, removal, inspection

and cleaning.

Particular attention should be paid to the ambient temperature when building the pump into

equipment. Use a rubber vibration isolator to separate the pump from other equipment and to

isolate the pump from the vibrations of other equipment. See “

0.4.2 Environmental conditions

for installation, storage and operation

” for details.

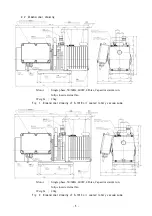

Fig. 3 Transportation method of the oil sealed rotary vacuum pump

Since the pump weighs as much as 20 kg, do not lift or transport it by yourself.

Doing so may cause an injury. Always carry out work with two people as shown

in Fig. 3.

If the pump is operated whilst it is tilted, placed on its side or upside-down,

the pump will be damaged. Install the pump level with the inlet facing up

as shown in Fig. 1,Fig. 2.

3.2 Lubrication

Remove the lubrication plug from the lubrication port, and add the pump oil which has been

delivered together with the pump or the pump oil specified by us (SMR-100) up to the range

marked with the red line on the oil level gauge. When making the first lubrication, add oil near

to the upper oil level limit shown on the oil level gauge. After lubrication, mount the lubrication

plug to the pump (see Fig. 4).

Always keep the oil level of the pump within the oil limit range shown on the oil level gauge

during operation. If the amount of oil is incorrect, the performance of the pump will deteriorate

resulting in the malfunctioning of the pump. When the amount of oil has reduced and the oil

level has reached an area below the lower red line which shows the lower limit on the oil level

gauge such that the level cannot be seen, the ultimate pressure increases and exhausting sound

may not cease.

Note

Caution