-2-

How it Works

The unit is designed to heat domestic hot water (DHW) using low temperature hot water (LTHW). The primary

circulating shunt pump mounted on the exchanger is for heat exchanger control only and is sized to pump the

correct volume of LTHW through the heat exchanger to ensure efficient operation.

When domestic hot water is required, the control valve modulates to allow LTHW to be pumped through the

exchanger. The required DHW outlet temperature can be set on the controller.

The temperature of the DHW is monitored by the strap-on sensor on the DHW outlet pipe. This sends a signal

to the controller in the panel that in turn modulates the control valve thereby maintaining the DHW outlet

temperature set on the controller.

If the DHW goes over temperature then an over heat stat shuts down primary circulating pump (and also the

secondary pump if fitted and controlled by the panel). The system can only be re-started when the temperature

has cooled down and after the high temperature re-set button has been pushed on the front of the panel.

To avoid the possibility of thermal siphoning back from the boiler return we recommend that non return valves

are incorporated into the pipe-work. Due to the high efficiency of the heat exchanger when there is no DHW

circulation it is possible to over heat the DHW and cause the stat to trip even when the primary shunt pump is

not running.

Time Clock / BMS Operation

As an additional option the unit can be supplied with either a time clock that is incorporated into the panel or

Building Management System interface signals.

During control times / schedules, the pump(s) run continuously.

When in AUTO control (by either BMS or time clock) only the operation of the pump(s) is controlled. The high

temperature over heat protection and the control of the modulating valve is independent of the auto pump

control operation.

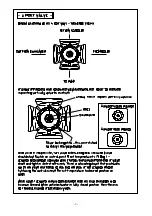

Four port valves are fitted as standard to all of the models in the range. Advantages of a four port valve are

that it allows the LTHW circulation to be maintained to and from the unit at all times. This:

•

avoids cold pipe work when exchanger not calling for heat

•

allows any other boiler safety & control functions to continue (such as over runs, etc)

•

enables the exchanger to be connected into the main primary loop rather than from a “tapping” into

the main primary flow and return.

Primary Pump Energy Saving Feature (if fitted)

As another additional option, the packaged unit can be fitted with an energy saving feature for the primary

shunt pump. In times of low demand, the pump shuts down, thus saving energy. As this corresponds to the

valve closing, then the boiler circuit is closed off as well, thus saving more energy from the primary heat

source. The pump shuts down when the actuator is less than 4% open, and the pump starts when the actuator

is more than 6% open.

The energy saving feature can be retro-fitted, but it does involve modifications to the actuator and the control

panel..

Commissioning

– as with all plant equipment, it is recommended that some commissioning takes place in

order to set up the equipment correctly and to check the settings. Contact our Sales Office for commissioning

rates if required.

Содержание UKE-8-50

Страница 3: ... 3 ...

Страница 9: ... 9 ...

Страница 13: ... 13 Examples of Gasket and Plate types ...