EVA-M8M - Hardware Integration Manual

3

Product handling & soldering

3.1

Packaging, shipping, storage and moisture preconditioning

For information pertaining to reels and tapes, Moisture Sensitivity levels (MSD), shipment and storage

information, as well as drying for preconditioning see the

EVA-M8M Data Sheet

[1] .

3.2

ESD handling precautions

ESD prevention is based on establishing an Electrostatic Protective Area (EPA). The EPA can be a small working

station or a large manufacturing area. The main principle of an EPA is that there are no highly charging materials

in the vicinity of ESD sensitive electronics, all conductive materials are grounded, workers are grounded, and

charge build-up on ESD sensitive electronics is prevented. International standards are used to define typical EPA

and can be obtained for example from International Electrotechnical Commission (IEC) or American National

Standards Institute (ANSI).

GNSS receivers are sensitive to ESD and require special precautions when handling. Particular care must be

exercised when handling patch antennas, due to the risk of electrostatic charges. In addition to standard ESD

safety practices, the following measures should be taken into account whenever handling the receiver.

•

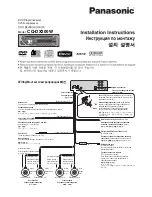

Unless there is a galvanic coupling between the local GND (i.e. the

work table) and the PCB GND, then the first point of contact when

handling the PCB shall always be between the local GND and PCB

GND.

•

Before mounting an antenna patch, connect ground of the device.

GND

Local GND

•

When handling the RF pin, do not come into contact with any

charged capacitors and be careful when contacting materials that

can develop charges (e.g. patch antenna ~10 pF, coax cable ~50-

80 pF/m, soldering iron, …)

•

To prevent electrostatic discharge through the RF input, do not

touch the mounted patch antenna.

•

When soldering RF connectors and patch antennas to the receiver’s

RF pin, make sure to use an ESD safe soldering iron (tip).

Failure to observe these precautions can result in severe damage to the GNSS receiver!

3.3

Soldering

3.3.1

Soldering paste

Use of "No Clean" soldering paste is strongly recommended, as it does not require cleaning after the soldering

process has taken place.

Stencil Thickness:

100 to 150 µm for base boards

The paste-mask geometry for applying soldering paste should meet the recommendations given in section

UBX-14006179 - R01

Advance Information

Product

handling & soldering

Page 27 of 45