u-line.com

27

Troubleshooting

Component Testing

NOTICE

Frequently toggling the compressor relay could force the

compressor into overload. The compressor will

automatically deactivate during an overload and will remain

deactivated until the overload switch cools, regardless of

relay and voltage state.

NOTICE

If the compressor is suspected of being faulty it is important

to verify all copper tubing, dryers, capillary lines,

evaporators and condensers are free from kinks, excessive

bends or blockages. A restriction in any of these

components would force the compressor to overload,

making it appear as if it is faulty.

If a component is suspected as being faulty, follow the

troubleshooting steps below to help isolate the cause.

1. Initiate Self Test Mode, address any current errors before

beginning component testing.

2. Activate the component’s relay or DC output through “Relay

Toggle” under the service menu.

3. Test for voltage at the component.

Voltage Present

If voltage is present and the component does not function, suspect a

faulty component. If the component being tested is the compressor,

make certain it is not overloaded by disconnecting power to the unit

for at least 15 minutes and re-testing.

No Voltage Present

If no voltage is present check for voltage at the relay / DC output.

Reference the diagram for component relay / DC output pins. If

voltage is present, suspect a faulty component cable. If voltage is not

present at the relay / DC output, cycle the power to the unit and

re-test. If voltage is still not present, suspect the main control of

being faulty.

Component Testing Example

Below is an example of how to properly test a component for

functionality. An evaporator fan is used.

Condition

Customer complains of the unit not cooling properly. The main

screen of the display lists an error “Temp Hi 12H+”. The compressor

seems to be functioning properly, however the evaporator fan does

not activate after a door cycle.

In the above case it would be wise to test the evaporator fan for

functionality.

Testing

1. Check “Self Test” for any additional errors that may be current.

2. Visually examine the fan through the fan cover. Note any ice

buildup. In this case no ice buildup was noticed. The fan appeared

as if it could spin freely.

3. Enter “Relay Toggle” and manually activate FAN1.

4. Check for fan operation. In this case the fan does not operate.

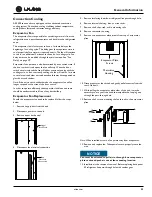

5. Remove the upper and lower back panel from the refrigeration

unit.

6. Ensuring the DC output is still active,

use a meter to check voltage at the fan

power connection point. In this instance

no voltage is present.

7. Ensuring the DC output is still active and

referencing the Connector & Pin ID

chart, a voltage test is performed across pins 1 and 6 of the header

labeled J4. In this case a stable 12 volts DC was noted.

8. Confirming that the board is sending voltage, the cabling between

the board and fan is inspected for damage. In this case some

damage is noted.

9. The fan cable harness is replaced, and the fan DC output is tested

again. It is noted the fan now spins freely.

10. The unit is then monitored for proper operation and any further

faults.

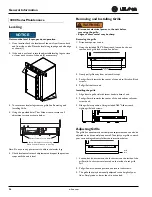

Relay Output

ID

Test

Point 1

Test

Point 2

Voltage

On

Voltage

Off

Comp

Pin J2-3

Pin J2-10

120

0

F-1

Pin J2-1

Pin J2-10

120

0

F-3 NA

---

---

---

---

L1

Pin J4-4

Pin J4-9

8-12 VDC

< 7 VDC

J2

J5

J4

J1

F1

J2

J4

J1

16

1

10

10

6

1

5

9

8

1

Connector & Pin ID

Voltage Checked

At Connection

J4

Voltage Checked

At These Pins