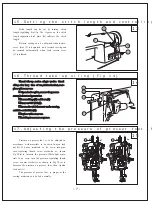

6.Installing the bobbin winder (Fig 4)

5.Installing belt guard(Fig 3)

4

3

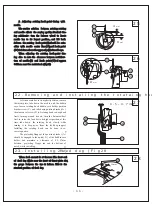

7.Lubrication (Fig 5)

5

-2-

H

L

O

I L

A

B

C

A

B

C

D

E

D

The belt guard should be installed for safety.

Align pulley (B) of the bobbin winder with the

outside of the belt , and there should be a proper

clearness between them , so that pulley (B) can be

contacted with the belt when stop latch thumb le-

ver (A) is depressed, thereby the belt drives prlley

(B) white the machine running , the bobbin winder

should be parallel with belt slit (E) of the table,

the fasten with two wood screw (D).

A. Oil amount

Oil amount must be oiled according to the

mark of drip pan. Mark (A) is the highest situation,

Mark (B) is the lowest situation , Note that oil

,

amount couldn t the lower than mark (B), otherwise

all parts of machine will appear heat and dead

point for not gaining oil.

b. Oiling

In lubruation, HA-8 sewing machine oil or HJ-7

machine oil must be used. Before running, the mach-

ine must be oiled at the mark (A).

c.Changing

Turn off the screw plugs (C), clean up the dirty

oil and the dust of drip pan, then fasten the screw

plugs (C), add fresh oil