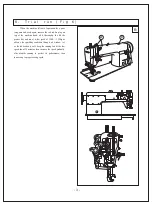

In general, the thread tension is to be adjusted

in accordance with materials thread and others.

In practice, the thread tension is adjusted ac-

cording to the stitches resulted to get the normal

stitches.

When adjusting the bobbin thread tension,

turn bobbin case tension spring screw (A) clock-

wise for more tension or turn the screw counter

clockwise for less tension.

It is a common practice to check the bobbin

thread tension. In case of polyester thread 50=,

hold the end of the thread. If the bobbin case falls

down slowly, the proper tension is obtained.

The needle thread tension should be ad-

justed with referance to the bobbin thread ten-

sion. The needle thread tension can be adjusted by

changing tension of the thread take-up spring ,sew-

ing range of the thread take-up spring, tension of

tension disc, and the position of thread guide.

.

.

.

.

.

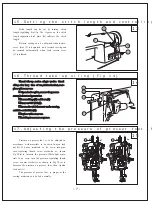

The normal sewing range of thread take-up sping

is 5~8mm. For sewing light weight materials( short

stitch), weaken the spring tension and widen the

sewing range of spring, while for sewing heavy

weight materials, strengthen the spring tension and

shorten the sewing range of spring .

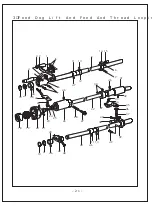

1) Adjusting the thread take-up spring tension

(Fig.18) .

Loosen tension stud set screw (A), turn ten-

sion stud (B) clockwise to make the spring get

more tension, or turn the tension stud counter

clockwise to make the spring get less tension, After

adjustment, Be sure to tight tension stud set screw (A).

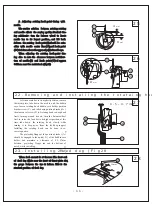

The method of adjustment:

Loose set screw (A) first, then to turn tension

stud(B) counter clockwise to release the tension of

:

19.Adjusting the thread take-up spring (Fig 18

、

19)

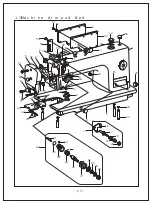

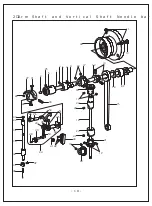

18.Adjusting the thread tension(Fig 16

、

17)

18

16

-8-

17

A

B

C

A

B

A