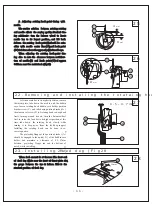

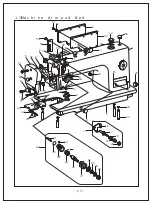

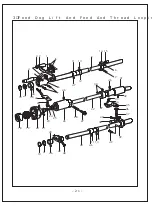

21.Timing between the needle and the rotating hook(Fig23

、

24

、

25

、

26)

24

-10-

23

22

A

B

C

D

E

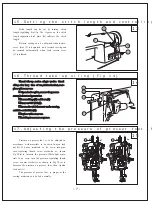

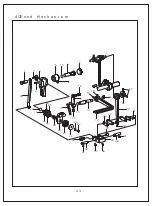

(B) The needle thread tension is too weak or

the bobbin thread is too strong, turn the tension

regulating thumb nut clockwise to make the needle

thread get more tension or turn the bobbin case ten-

sion regulating screw counter clockwise with small

plastic screw driver to make the bobbin thread get

less tension (Fig.22)

( c) Other abrormal stitches as shown in Fig.20

(d) .(e) , adjustment can be made which reference to

the above methods.

.

.

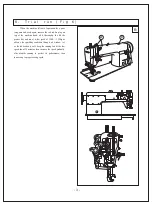

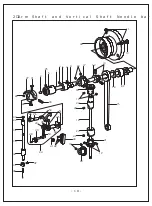

1 Adjusting the position of needle bar

Turn the balance wheel to locate the needle

bar ( C ) at its lowest position, remove the rubber

plug in the face plate (A), then loosen the needle

bar ( C ) connecting stud clamping screw (B) and move

the needle bar ( C ) vertically to locate the timing

position ( The timing position of the needle bar is:

when the needle bar at its lowest position, the center

of needle eye ( D ) coincide with inside surface (E)

of bobbin case holder as shown in Fig.24). Tighten

clamping screw(B), plug the rubber plug.

.

.