GC0303

2000spm

8mm

12mm

1800spm

GC0303CX

8mm

3.5-5.5mm

DP

×

17(20#

~

23#)

DP

×

17(25#)

8mm

16mm

370W

1

B

A

C

2

G

F

E

1

0 - 1

2

mm

D

C

B

A

20~30

1.Main techanical specifications

3.Installing the motor(Fig.1)

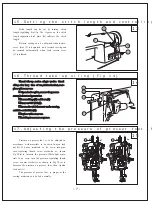

4.Connecting the clutch lever to the pedal(Fig.2)

2.Preparation

-1-

Align machine balance wheel belt groove (A)

with motor pulley belt groove (B) by moving the

motor(C) leftward or rightward. Be sure the belt is

not touch with table.

(1)Cleaning machine

Clean off the grease and dusts on the Surface of ma-

chine with gasoline and soft cloth.

(2)Inspection

Before use a thorough inspection should be done upon

the machine. Turn balance wheel slowly to see if there is

any obstacle , collision and uneven resistance between

parts. If there is , adjustment should be done before

operation.

a. The optimum tilt angle of pedal with floor is

approx 15 degree.

b. Adjust the clutch of the motor so that clutch

lever (C) and draw bar (B) run in line as Fig. 6, the

machine would have stable motion and long using.

c. The machine balance wheel should rotate

conter clockwise for normal sewing when view

from opposite side of the balance wheel. The motor

rotates in the same direction. The rotation can be

reversed by reversing (turn over 180 deg.) the plug of

the motor.

d. Adjust the tension of V-belt F by moving

the motor vertically. The proper tension of V-belt

is a slack of 10~12mm when the belt is depressed

(at the belt pan) by finger.

Medium and heavy duty

Auto-lubricating big rotating hook

Auto lubrication

Model

Application

Max. Sewing Speed

Max. Stitch length

Max. Sewing Capacity

Alternate presser foot lift volume

Needle

By hand

By knee

Hook

Lubrication

Motor power

Presser

foot lift