PDx-170-57-E / TMCM-170 Hardware Manual (V1.10 / 2011-NOV-24)

14

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

“Actual Commutation Offset” gives the angular relationship between motor and encoder.

Therefore this parameter has to be stored correctly in EEPROM before power on! Do not

enable this mode, before the parameter has been set correctly. Mode 4 helps for the very

first initialization of this mode.

Mode 4

helps to do a first initialization and tuning of mode 3. It searches for the N-channel

reference point first, and then does a

mode 2

initialization to determine the correct setting

for the “Actual Commutation Offset”. The encoder N-channel polarity has to be high active

for this mode (the actual setting of the encoder null polarity has no influence in this mode),

and, additionally, you have to specify the polarity of the encoder A- and B-channel upon N-

channel activity using the setting “Encoder Null Polarity”, bits 1 and 2. The correct setting of

this depends on the encoder. If the N-channel referencing fails, the motor does two full

rotations and then stops. Try again with reversing the “Encoder Null Polarity”. After

successfully initializing the “Actual Commutation Offset”, you can try moving the motor and

tune the offset, if desired. Then store the offset and switch to

mode 3

. If any encoder errors

are flagged during operation of the motor, retry with a modified setting for A- and B-

channel polarity.

Attention: Initialization modes 1 to 4 apply a high current to the motor for a few seconds. Be sure

to parameterize the initialization current correctly (i.e. not more than 2* the maximum

rated motor current) before first powering on the unit.

The quality of the initialization phase result can be checked by rotating the motor left and right at the

maximum velocity (use a velocity setting slightly higher than the motor can follow). Maximum velocity

for left and right direction shall not differ by more than a few percent. Also make some checks if

results are reproducible.

Whenever changing one of these parameters, re-power the unit to restart initialization phase!

6.3

Encoder setting

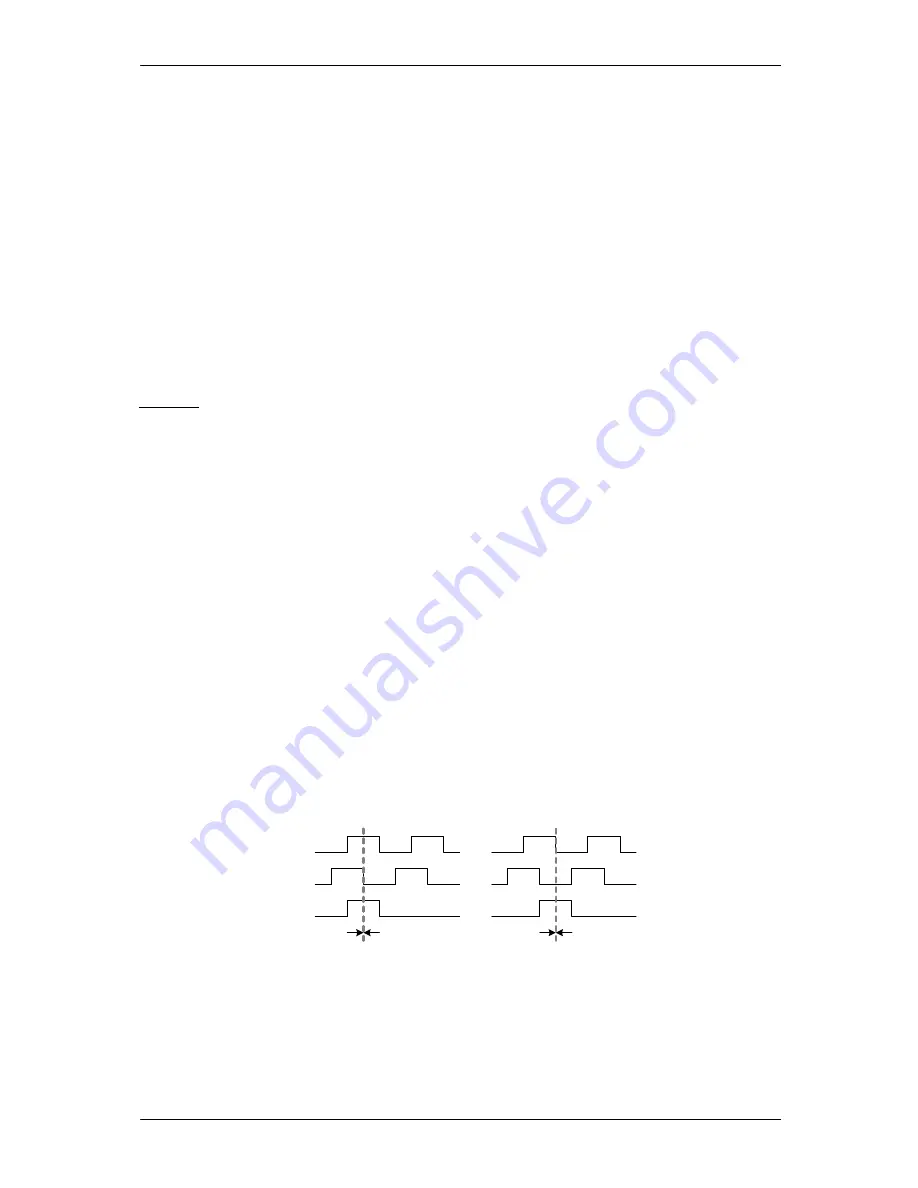

The N-channel (index channel) of the encoder is not required for motor operation, but it is very good

for motor initialization, because it gives an absolute and exact reference point. So, the motor

initialization modes 3 and 4 use the N-channel for motor initialization. Behavior of the N-channel

signal is very dependent on the encoder type and has to be taken into account for the setting of the

TMCM170 encoder interface. Please refer to the following figure for correct setting of the Encoder Null

Polarity flag.

A wrong setting may either hinder the module from initializing the sine mode, or might lead to the

Encoder Error flag being set, in spite of correct encoder function.

zero event

Enc-A

Enc-B

Enc-N

(index)

Set Encoder Null

Polarity to

binary 011

Set Encoder Null

Polarity to

binary 001

zero event

CW turn

CCW turn

CW turn

CCW turn

0

1

0

0