Monopack 2 Manual V1.04

22

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

4.6

Alarms and Errors

4.6.1

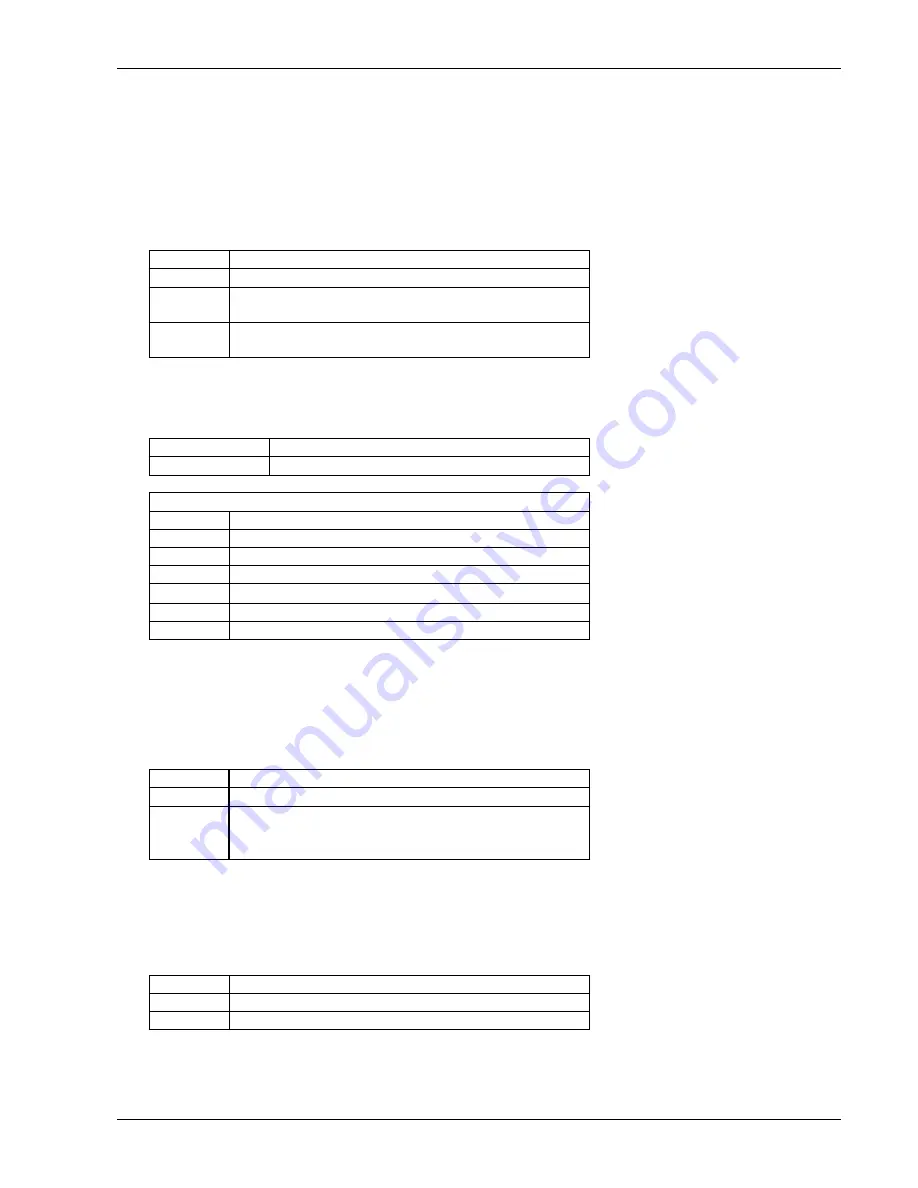

Alarm Mode ($51)

Set up the alarm mode. The alarm mode determines if the motor is to be powered off when an external alarm

(alarm input set high) or a driver error occurs. The motor can be powered on again by resetting the alarm using

command $74 (s. 4.6.2).

CMD

$51

P0

Parameter storage control (s. 4.1)

P1

0:

only stop motor in case of external alarm

1:

stop and power off in case of external alarm

P2

0:

do not stop motor in case of driver error

1:

stop and power off in case of driver error

4.6.2

Reset Alarm Output ($74)

Reset the alarm output and return the alarm reason as answer.

CMD

$74

P0

0

Answer

CMD

$74

P0

0

P1

Driver error (0=no/1=yes) (short circuit, overload, etc.)

P2

Deviation error (0=no/1=yes) (s. 4.5.5)

P3

External alarm input (0=no/1=yes)

P4

Travel check tolerance error (0=no/1=yes) (s. 4.4.5)

P5

Position correction error (0=no/1=yes) (s. 4.5.6)

4.7

Other Settings

4.7.1

Enter Step/Direction Mode ($50)

This command can be used to switch the Monopack back to step-/direction mode (e.g. after changing parameters

or resetting an alarm).

CMD

$50

P0

0

P1

0: step/direction mode

1: command mode (any other command will also

switch to command mode)

4.7.2

Set CAN receive ID and RS485 ID ($55)

Set the CAN identifier which will be used for receiving data from the CAN bus and the RS485 address. Please note

that the LSN of the CAN receive ID and the LSN of the RS485 address are set by the hexadecimal switch and not by

command. Please see also section 3.2.2 and 2.8.

CMD

$55

P0

Parameter storage control (s. 4.1)

P1 – P4

32 bit unsigned long ID # (only 11 bits are used)