5

PIPEMASTER™ Model PFM816

92-1412 Rev. 150925

2.5 AREA EQUIPMENT

•

Secure the pipe with clamps, vises, chains or straps.

•

Ensure that both sides of the pipe at the cut site is fully supported so that the

pipe will not move after the cut is completed. Long lengths of pipe may be

under load and the separation of the pipe can release pressure. This pressure

can cause both sides of the pipe to move.

2.6 TOOL CARE

•

Keep tools in good operating condition. Sharp tool bits perform better and are

safer than dull tool bits.

•

Do not use damaged tools. Always check your tools for damage especially if a

tool has malfunctioned, been dropped or hit, check it for damage.

•

Before you start operating the equipment, do no-load tests and feed function

checks.

Содержание PIPEMASTER PFM816

Страница 1: ...Operation Manual 92 1412 Rev 150925 PIPEMASTER Model PFM816 ...

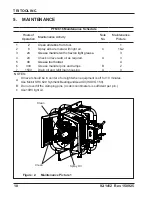

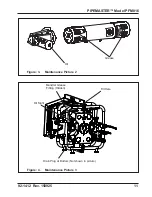

Страница 14: ...12 TRI TOOL INC 92 1412 Rev 150925 Grease Fitting Grease Fitting Figure 5 Maintenance Picture 4 ...

Страница 28: ...This Page is Intentionally Left Blank ...

Страница 30: ...This Page is Intentionally Left Blank ...

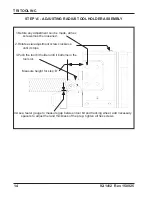

Страница 44: ...42 TRI TOOL INC 92 1412 Rev 150925 PFM 816 SUB ASSEMBLY 1 OF 3 P N 02 2566 ...