20

TRI TOOL INC.

92-1412 Rev. 150925

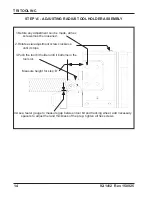

12. Bring the head back to its maximum retracted position.

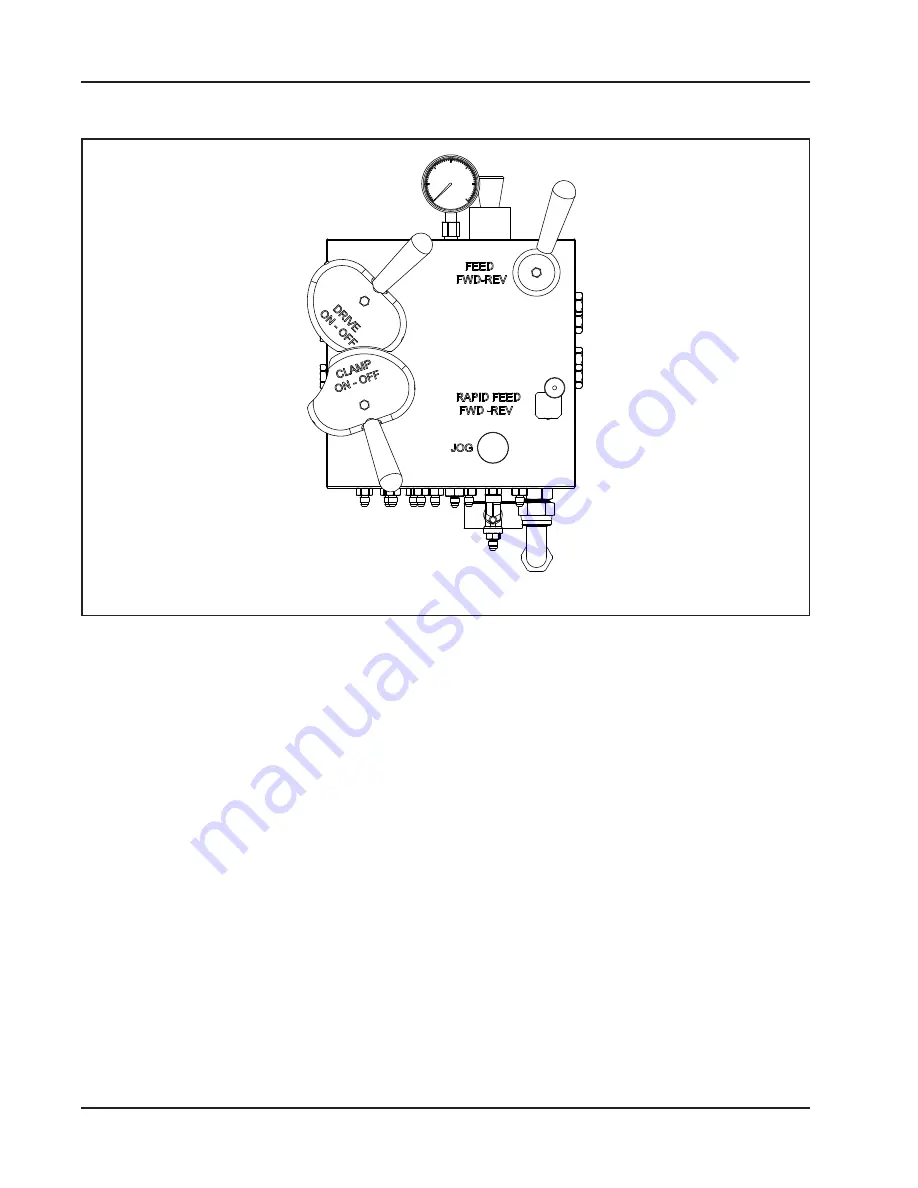

Figure: 6. PFM Front View

13. Adjust the dial indicator to “0”.

14.

If you are authorized to do so, open the control panel and ask for the flow

control key from your supervisor.

15. Unlock the feed rate knob with the key.

16. Shift the feed lever to forward and time for one full minute.

17. After one minute, stop the feed, and read the dial indicator and see if the

reading is equal to 0.432” plus or minus 0.005”.

18. If the reading is too high or to low, re-adjust the knob accordingly and repeat

until the desired feed rate is obtained.

19. When all set ups are done according to the tool holder set up instructions,

and the previous instructions, insert the PFM into the pipe.

20. Make sure that the head is back before inserting the PFM into the pipe.

21. Bring the tool holders tracking wheels about 1” from the end of the pipe.

22. Clamp the PFM into the pipe by shifting the clamping lever to clamp.

23. The PFM is clamped in the pipe when the pressure indicator reaches its

maximum of 2000 PSI approximately. (With the correct jaw blocks.)

Содержание PIPEMASTER PFM816

Страница 1: ...Operation Manual 92 1412 Rev 150925 PIPEMASTER Model PFM816 ...

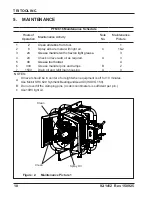

Страница 14: ...12 TRI TOOL INC 92 1412 Rev 150925 Grease Fitting Grease Fitting Figure 5 Maintenance Picture 4 ...

Страница 28: ...This Page is Intentionally Left Blank ...

Страница 30: ...This Page is Intentionally Left Blank ...

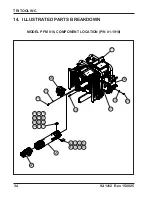

Страница 44: ...42 TRI TOOL INC 92 1412 Rev 150925 PFM 816 SUB ASSEMBLY 1 OF 3 P N 02 2566 ...