19

PIPEMASTER™ Model PFM816

92-1412 Rev. 150925

6.2 OPERATING INSTRUCTIONS

1. Measure the I.D. of the pipe to be machined.

2. Select the right set of Jaw blocks to Clamp in the pipe. Refer to section 8,

Standard Head, Jaw Blocks and Guide Wedges,

3. Install the jaw blocks on the 12 Clamp pins.

4. Adjust the tool holders according to the previous tool holder adjustment

instructions.

5. Connect the 3 hydraulic hoses to the PFM.

6. Connect power to the HPU.

7. Bring the HPU pendant close to the PFM controls.

8. Turn on the drive, refer to Fig. 6 and count the head rotation for a full minute.

Example:

72 RPM.

9. Remember this number and multiply it by the feed rate.

•

Formula:

feed rate per revolution x rotation per minute = linear travel per

minute.

•

Example:

0.006” per revolution x 72 RPM = 0.432 ” of linear travel of the

head.

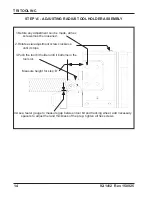

10. Set the feed rate of the PFM by using a magnetic base dial indicator attached

to the back of the PFM.

11. Indicate the end of one of the torque bar.

Содержание PIPEMASTER PFM816

Страница 1: ...Operation Manual 92 1412 Rev 150925 PIPEMASTER Model PFM816 ...

Страница 14: ...12 TRI TOOL INC 92 1412 Rev 150925 Grease Fitting Grease Fitting Figure 5 Maintenance Picture 4 ...

Страница 28: ...This Page is Intentionally Left Blank ...

Страница 30: ...This Page is Intentionally Left Blank ...

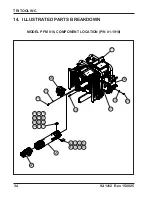

Страница 44: ...42 TRI TOOL INC 92 1412 Rev 150925 PFM 816 SUB ASSEMBLY 1 OF 3 P N 02 2566 ...