7

PIPEMASTER™ Model PFM816

92-1412 Rev. 150925

3. GENERAL DESCRIPTION

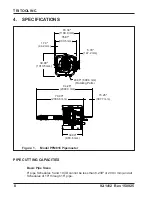

The Model PFM 816 PIPEMASTER™ is a portable ID mount machine tool for

beveling, facing, and/or counter-boring 8” through 16” pipe.

The tool is configured with twin hydraulic motor drives that power helical drive

gears attached to the main spindle for smooth power delivery for optimal surface

finish.

A set of two hydraulic cylinders with rapid and slow feed control, the advance

and feed cutting head into the pipe. A 4" (101.6 mm) diameter mandrel shaft is

provided for optimum stability during heavy cutting operations.

One hydraulically actuated mandrel head with extended mounting ring

assemblies and mounting pads covers the complete mounting range of the tool.

The lifting frame does not require removal or separate lay down stands. The tool

can be lifted for mounting in horizontal, vertical-up, or vertical-down positions for

prepping on-site pipes

The tool accepts the torque that it generates through the mandrel.

The hydraulically expanded mandrel provides fast, accurate self-centering and

alignment.

All wrenches needed for operation (less Tool Bits) are provided with the system.

The lathe is provided with a combination lifting frame and stand .

The mandrel head provides 40,000 lbs. of clamping force. (2000 PSI Hydraulic

Pressure)

The mandrel head and adapters cover the full mounting range of the tool.

The power train uses a precision helical cut gear system, for precise weld

preparation.

The lathe has a 4.0” (101.6 mm) diameter mandrel shaft for optimum rigidity.

Five and one-half (5.5") inches (139.7 mm) of feed travel allow for easy axial

positioning.

Extra feed travel is provided to allow the tool to handle heavy wall pipe.

Four (4) ID tracking tool modules allows distributing the cutting loads to more tool

bits to handle greater wall thickness.

Two (2) torque acceptance bars insure greater torque handling and a balanced

load for accurate end facing.

The hydraulic drive system delivers smooth power for optimum cutting.

A chip guard with a Shut-Off switch is supplied for the safety of the operator.

An interlocking safety mechanism is supplied to avoid unclamping the mandrel

while the headstock is rotating.

A 'Jog' switch is supplied to rotate the cutting head for set up.

Содержание PIPEMASTER PFM816

Страница 1: ...Operation Manual 92 1412 Rev 150925 PIPEMASTER Model PFM816 ...

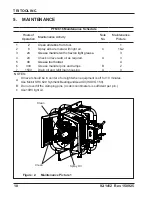

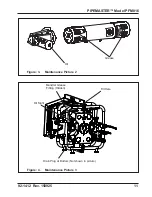

Страница 14: ...12 TRI TOOL INC 92 1412 Rev 150925 Grease Fitting Grease Fitting Figure 5 Maintenance Picture 4 ...

Страница 28: ...This Page is Intentionally Left Blank ...

Страница 30: ...This Page is Intentionally Left Blank ...

Страница 44: ...42 TRI TOOL INC 92 1412 Rev 150925 PFM 816 SUB ASSEMBLY 1 OF 3 P N 02 2566 ...