RLC-SVX19A-E4

53

Periodic Maintenance

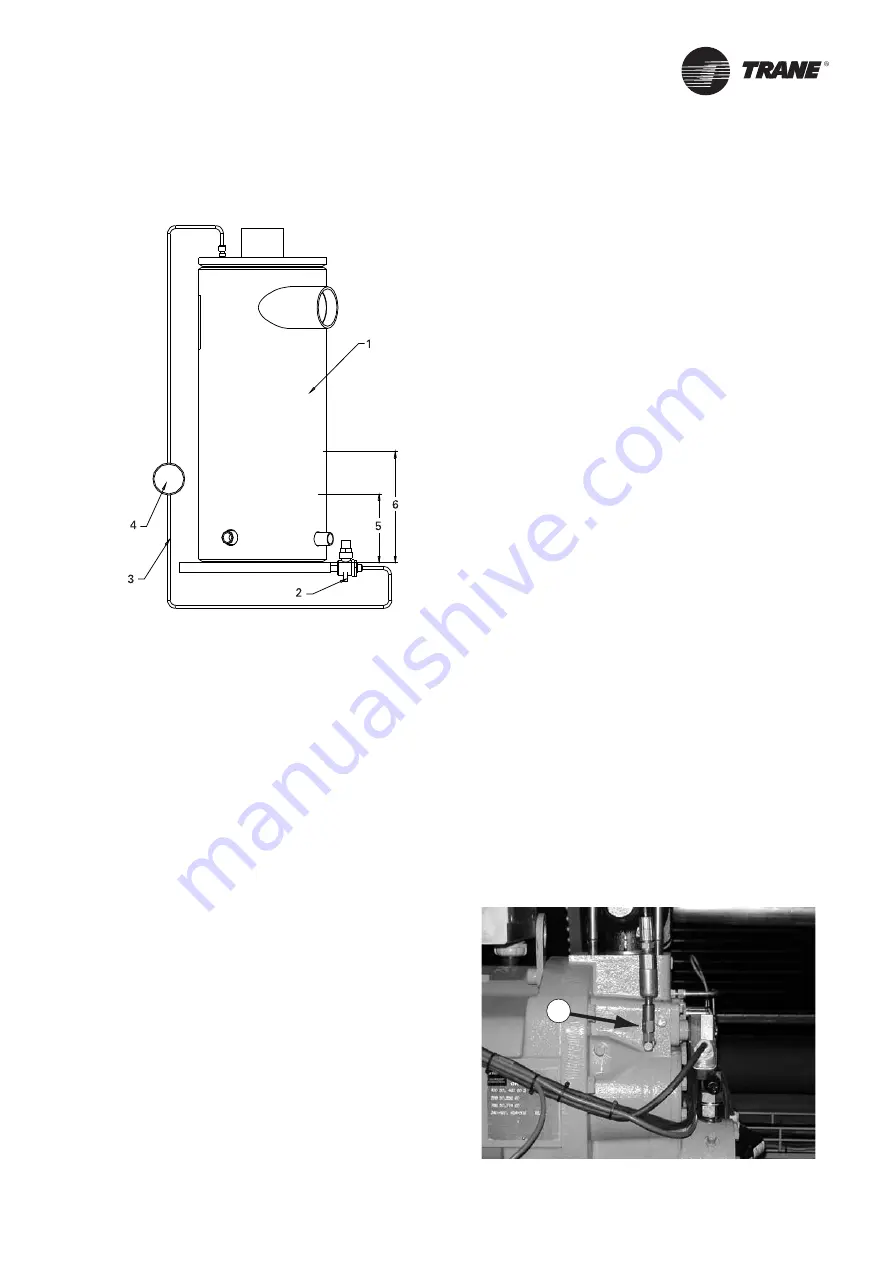

Figure 24 – Oil system schematic: Oil level measurement.

1 = Oil separator

2 = Valve

3 = 1/4” refrigeration hose

4 = Sight glass

5 = Minimum oil level

6 = Maximum oil level

How to measure the

oil level:

1.

Use the oil drain valve on the oil line and the

service valve on the oil separator (bottom side). This

measurement can be made, when the circuit is not

running. Note: the bottom plate of the oil separator is

approximately 25mm thick.

2. The initial oil charge should be approximately at the

level in of the above chart. This is the approximate

oil level if all the oil is in the oil lines, fi lter, and oil

sump, and the unit is in vacuum so that there is no

refrigerant dissolved in the oil.

3. After the unit has run for a while, the oil level in the

sump can vary greatly. However, if the unit has run at

“normal” conditions for a long time, the level should

resemble the level in the above chart: 25mm to

101mm is acceptable.

The fi eld charging procedure depends on the

circumstances that resulted in the need for oil charge.

1.

Some services procedures may result in loss of

small quantities of oil that must be replaced (oil

analysis, compressor fi lter replacement, re-tubing

the evaporator, and so forth).

2. Additionally, some maintenance procedures

may result in virtually all the oil being removed

(compressor motor burn or total removal of the

charge to trouble shoot a unit).

3. Finally, leaks may result in a loss of oil that must be

replaced.

Prelubrication

Prior to the oil charging procedure, a small amount of oil

shall be injected in the port labeled “1” on Figure 26 Oil

pushed into this location drains into the discharge port,

which allows the oil to effectively cover the rotor end

faces and rotor tips.

The only issue is that if the schraeder is not present

on this port, the 7/16 o-ring boss plug normally in this

location will have to be replaced by a 7/16-schraeder

fi tting (Trane part number VAL07306).

If this part is not available quickly, schraeder fi tting 2 or

3 (Figure 26) could be removed and put in location 1. The

plug would then replace the removed schraeder fi tting.

1.

Add 7/16 schraeder port where plug is today

(Figure 26).

2. Pull compressor and unit into Vacuum.

3. Connect oil line to port (Figure 25).

4. Let vacuum draw in ½ litre of oil.

Option: pump in ½ litre of oil. In any case, never

complete the entire oil charge by this port. This could

lead to drastic damages for the compressor. Oil injected

should be preheated.

5. Remove the oil line.

Figure 25

1

Содержание RTAF HE Series

Страница 3: ...RLC SVX19A E4 3...

Страница 36: ...RLC SVX19A E4 36 General Electrical Recommendations Figure 19 Warning Label...

Страница 59: ...RLC SVX19A E4 59 Notes...