18-CD19D5-25

3

Installer’s Guide

INSTALLATION INSTRUCTIONS

General Installation Instructions

3

Location and Clearances

4

Outline Drawings

5

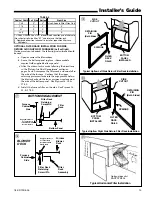

Upflow Installation

7

Downflow Installation

7

Horizontal Installation

7

Air For Combustion and Ventilation

8

Duct Connections

10

Return Air Filters

11

General Venting Instructions

16

Venting Material

16

Venting Tables

18

Horizontal Venting

21

Venting Through The Wall

21

Venting Through The Roof

25

Downward Venting

25

Venting Through a Masonry Chimney

26

Condensate Drain Instructions

27

Electrical Connections

29

Field Wiring Diagrams

29

Gas Piping

32

Combustion Input Checks

33

Start Up and Adjustment

35

Preliminary Inspections

35

Lighting Instructions

36

Sequence Of Operation

36

Control And Safety Switch Adjustments

36

Airflow Adjustment

37

Abnormal Conditions

37

IFC Error Flash Code

39

Contents

▲

WARNING

!

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly could re-

sult in serious injury, death or property damage.

Improper servicing could result in dangerous opera-

tion, serious injury, death, or property damage.

GENERAL INSTALLATION INSTRUCTIONS

The manufacturer assumes no responsibility for equip-

ment installed in violation of any code or regulation.

It is recommended that Manual J of the Air Condition-

ing Contractors Association (ACCA) or A.R.I. 230 be fol-

lowed in estimating heating requirements. When esti-

mating heating requirements for installation at alti-

tudes above 2000 ft., remember the gas input may need

to be reduced (See High Altitude Installation).

Material in this shipment has been inspected at

the factory and released to the transportation

agency without known damage. Inspect exterior

of carton for evidence of rough handling in ship-

ment. Unpack carefully after moving equipment

to approximate location. If damage to contents is

found, report the damage immediately to the de-

livering agency.

Codes and local utility requirements governing the

installation of gas fired equipment, wiring, plumbing,

and flue connections must be adhered to. In the ab-

sence of local codes, the installation must conform with

latest edition of the National Fuel Gas Code ANSI

Z223.1 • National Installation Code, CAN/CGA B149.1.

The latest code may be obtained from the American Gas

Association Laboratories, 400 N. Capitol St. NW,

Washington D.C. 20001.

1-800-699-9277 or www.aga.org

These furnaces have been classified as CATEGORY IV

furnaces in accordance with latest edition of ANSI

Z21.47 • CAN/ CGA 2.3 standards.

Category IV furnaces operate with positive vent static

pressure and with a flue loss less than 17 percent.

These conditions require special venting systems, which

must be gas tight and water tight. These Category IV

Direct Vent furnaces are approved for installation in

Manufactured/ Mobile housing when used with

BAYMFGH100A.

▲

CAUTION

!

T

o prevent shortening its service life, the furnace

should not be used as a “Construction Heater” during

the finishing phases of construction until the require-

ments listed in item 9, a-g of the safety section of this

publication have been met. Condensate in the pres-

ence of chlorides and fluorides from paint, varnish,

stains, adhesives, cleaning compounds, and cement

create a corrosive condition which may cause rapid de-

terioration of the heat exchanger.

▲

CAUTION

!

Do NOT install the furnace in a corrosive or contami-

nated atmosphere.

7. If improper venting is observed during any of the

above tests, the venting system must be corrected

in accordance with the National Fuel Gas Code,

ANSI Z221.1/ NFPA 54 and/ or CAN/ CGA B149 In-

stallation Codes.

8. After it has been determined that each appliance

connected to the venting system properly vents

where tested as outlined above, return doors, win-

dows, exhaust fans, fireplace dampers and any

other gas-fired burning appliance to their previous

conditions of use.